What is the basic working principle of a 90° Polarized Rotary Joint?

The 90° Polarized Rotary Joint is a sophisticated microwave component designed to transfer electromagnetic signals between stationary and rotating parts of a system while maintaining polarization at a 90-degree angle. At its core, this device utilizes carefully engineered waveguide structures that allow radio frequency (RF) energy to propagate seamlessly across the rotational interface. The basic working principle involves specialized internal geometries that permit continuous rotation while preserving signal integrity, ensuring that polarization remains stable throughout the full 360-degree rotation cycle, making the 90° Polarized Rotary Joint essential for applications requiring reliable signal transmission in rotating microwave systems.

Fundamental Operation Principles of 90° Polarized Rotary Joints

Electromagnetic Wave Propagation in Rotary Joints

The fundamental operation of a 90° Polarized Rotary Joint relies on sophisticated electromagnetic wave propagation principles. When a microwave signal enters the rotary joint, it encounters a carefully designed transition from the fixed waveguide section to the rotating section. This transition must maintain impedance matching to prevent signal reflections while supporting the desired polarization state. The electromagnetic fields within the 90° Polarized Rotary Joint are configured to ensure that the electric field vectors remain perpendicular to the direction of propagation throughout the rotation. Advanced Microwave Technologies' rotary joints employ precision-machined components with tight tolerances to maintain this field orientation, ensuring minimal signal distortion even during continuous rotation.

The waveguide structures within these rotary joints typically feature specialized geometries such as choke flanges or quarter-wave transformers that help maintain consistent electrical performance regardless of the rotational position. These design elements create electrical boundaries that contain the microwave energy within the desired path while eliminating unwanted modes that could cause signal degradation. Additionally, the 90° Polarized Rotary Joint incorporates specialized RF transitions that allow signals to propagate through the mechanical rotation interface without introducing phase distortions or impedance mismatches. Advanced Microwave's engineering team utilizes sophisticated simulation tools to optimize these transitions, ensuring that the electromagnetic fields maintain their integrity throughout the entire rotation cycle, resulting in stable performance across wide frequency ranges up to 40 GHz.

Mechanical Construction and Materials

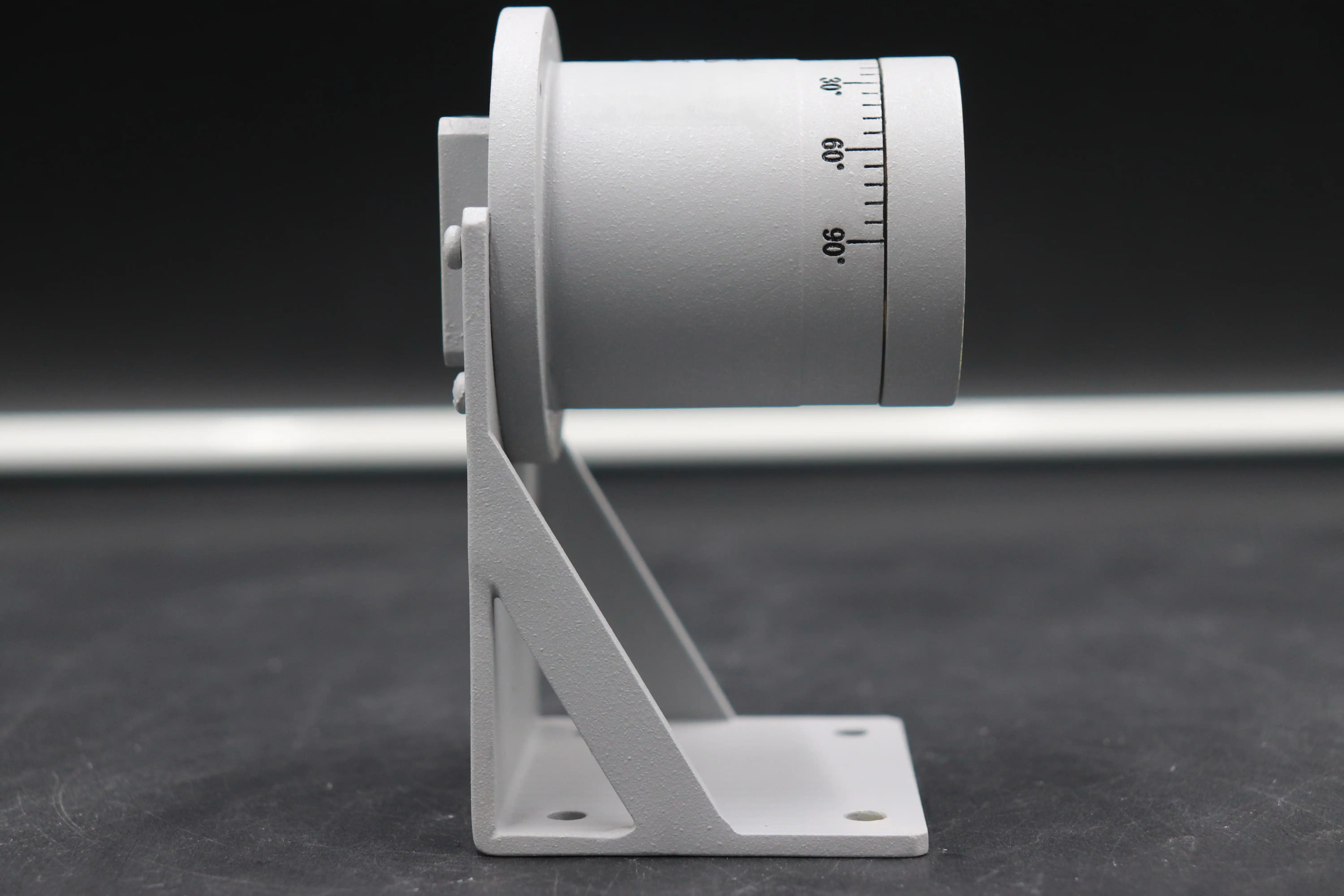

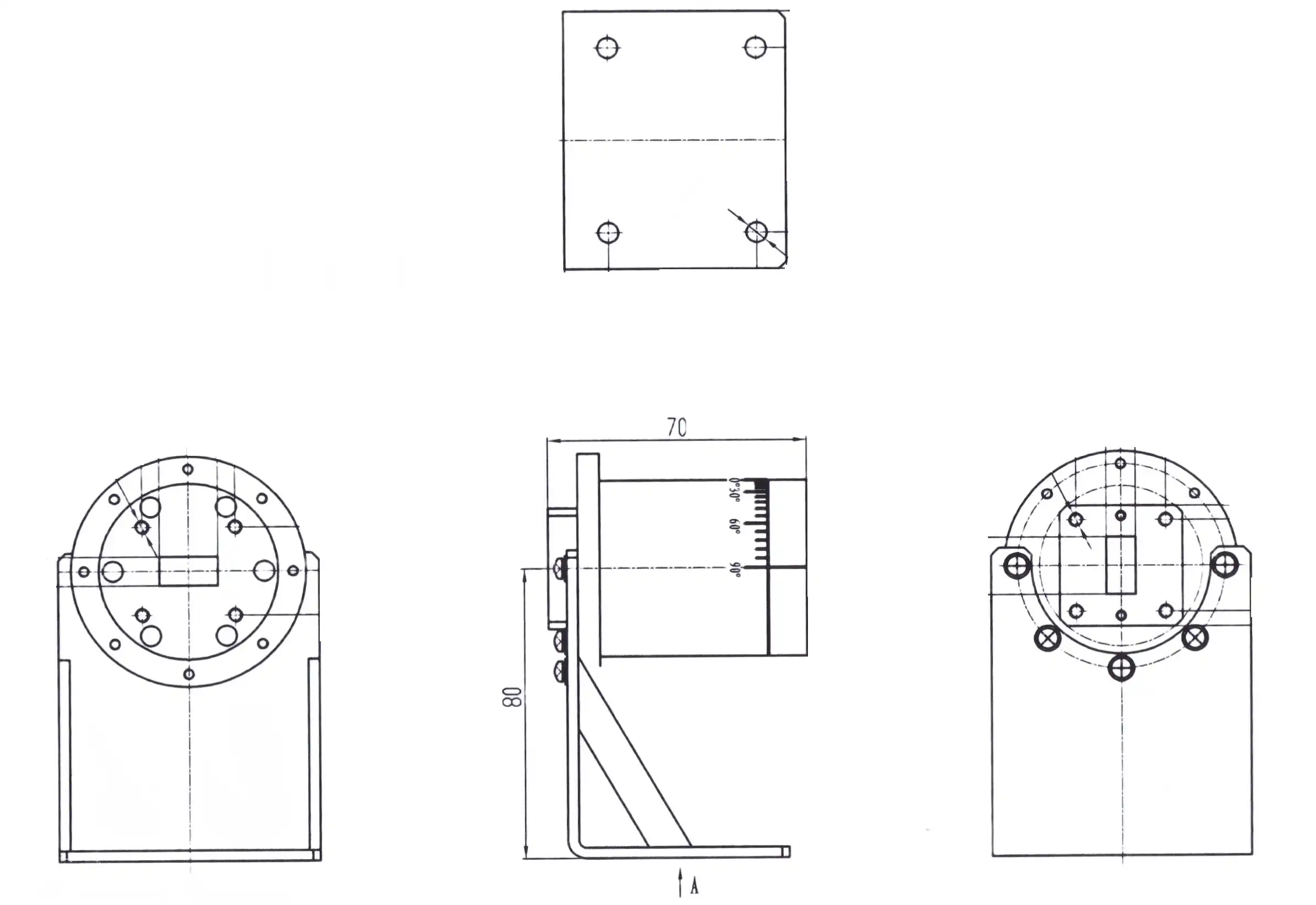

The mechanical construction of a 90° Polarized Rotary Joint is equally critical to its operational performance. These devices must balance precise mechanical tolerances with robust construction to withstand operational stresses while maintaining RF performance. Advanced Microwave Technologies employs high-grade materials such as aluminum and stainless steel in the construction of their rotary joints, providing excellent conductivity for RF signals while offering resistance to corrosion and wear. The bearings used in these rotary joints are specially selected to provide smooth rotation with minimal friction, ensuring long-term reliability even under continuous operation conditions.

The manufacturing process involves precision machining techniques to achieve the exact dimensions required for optimal RF performance. Critical features such as the gap between the rotating and stationary sections must be maintained within micron-level tolerances to ensure consistent electrical performance. Advanced Microwave Technologies' manufacturing facilities include climate-controlled environments and advanced CNC machinery to maintain these precise tolerances. The assembly process incorporates rigorous quality control procedures to verify both mechanical and electrical specifications before final testing. Each 90° Polarized Rotary Joint undergoes detailed dimensional inspection and mechanical testing to confirm smooth rotation, followed by comprehensive RF testing to verify electrical performance parameters including insertion loss, VSWR, and polarization purity across the specified frequency range, ensuring that customers receive products that meet the exacting standards required for satellite communications, defense systems, and other critical applications.

Polarization Control Mechanisms

The distinctive feature of a 90° Polarized Rotary Joint is its ability to maintain polarization at the specified 90-degree angle throughout rotation. This capability is achieved through specialized polarization control mechanisms that preserve the orientation of the electromagnetic field vectors as they propagate through the joint. Advanced Microwave Technologies implements several innovative techniques to accomplish this polarization control. One common approach involves the use of carefully designed mode converters that transform the incoming signal into a mode that is rotationally symmetric, allowing it to pass through the rotational interface without polarization degradation.

The internal structure of the 90° Polarized Rotary Joint incorporates precision-machined components that maintain the exact geometric relationships needed for proper polarization control. These components often include specialized polarizing elements that ensure the electric field maintains its orientation relative to the waveguide structure. The polarization control mechanisms must account for various operational factors including frequency dependencies, temperature variations, and mechanical wear. Advanced Microwave's engineering team employs sophisticated simulation and testing methodologies to validate the polarization performance across all operational conditions. The resulting 90° Polarized Rotary Joint provides exceptional polarization stability, typically maintaining cross-polarization isolation exceeding 30 dB across the specified frequency band. This performance level is critical for applications such as satellite communications where precise polarization control directly impacts system performance and channel isolation. The company's commitment to quality and precision ensures that each rotary joint maintains its polarization specifications throughout its operational lifetime, providing customers with reliable performance for their most demanding applications.

Performance Characteristics and Technical Specifications

Signal Integrity and Loss Considerations

Signal integrity is paramount in microwave systems, and the 90° Polarized Rotary Joint plays a critical role in maintaining this integrity across rotational interfaces. The primary concern in rotary joint design is minimizing insertion loss while maintaining consistent performance throughout rotation. Advanced Microwave Technologies has developed specialized techniques to address these challenges, resulting in rotary joints with ultra-low insertion loss typically less than 0.5 dB across the operational frequency range. This exceptional performance is achieved through precision manufacturing that ensures optimal alignment of waveguide sections and minimizes gaps that could cause signal leakage or reflections.

The 90° Polarized Rotary Joint must also maintain low VSWR (Voltage Standing Wave Ratio) to prevent signal reflections that could degrade system performance. Advanced Microwave's design approach includes carefully calculated impedance matching sections that provide smooth transitions between the various components within the rotary joint. These transitions are optimized using sophisticated electromagnetic simulation tools and verified through rigorous testing. The resulting rotary joints maintain VSWR typically below 1.3:1 across their specified frequency range, ensuring maximum power transfer and minimal signal reflection. Temperature stability is another crucial factor affecting signal integrity in practical applications. The 90° Polarized Rotary Joint incorporates materials with matched thermal expansion coefficients to maintain critical dimensions and alignments across a wide temperature range. Advanced Microwave Technologies conducts extensive environmental testing to verify performance under varying temperature conditions, ensuring that the rotary joints maintain consistent electrical characteristics in real-world operating environments. This attention to signal integrity details makes these components ideal for applications requiring high reliability and consistent performance, such as satellite communications systems where signal quality directly impacts overall system effectiveness.

Frequency Range and Power Handling

The frequency range and power handling capabilities of a 90° Polarized Rotary Joint are key specifications that determine its suitability for specific applications. Advanced Microwave Technologies offers rotary joints covering a wide spectrum of frequencies, with solutions available for ranges from L-band through Ka-band and beyond. Each frequency range presents unique design challenges that must be addressed to achieve optimal performance. At higher frequencies, manufacturing tolerances become increasingly critical as wavelengths decrease, requiring exceptionally precise machining and assembly processes. The company's advanced manufacturing capabilities enable the production of rotary joints with consistent performance even at frequencies extending up to 40 GHz.

Power handling capability is another crucial specification for many applications. The 90° Polarized Rotary Joint must efficiently transfer power without overheating or suffering electrical breakdown. Advanced Microwave's rotary joints are designed with careful consideration of power dissipation factors, incorporating thermal management techniques to handle power levels up to 50 W continuously. The internal structures are designed to minimize peak electric field intensities that could lead to breakdown at higher power levels. Material selection also plays a significant role in power handling capability, with high-conductivity materials used for critical RF surfaces to minimize resistive losses. For applications requiring higher power handling, Advanced Microwave Technologies offers customized solutions with enhanced cooling mechanisms or specialized materials. The company's engineering team works closely with customers to understand their specific requirements and develop rotary joints that provide the optimal balance between frequency coverage, power handling capability, and other critical performance parameters. This customization capability ensures that each 90° Polarized Rotary Joint meets the exact needs of its intended application, whether for high-power radar systems or sensitive satellite communication equipment.

Durability and Environmental Performance

Reliability in challenging environments is a hallmark of Advanced Microwave Technologies' 90° Polarized Rotary Joints. These components are engineered to provide consistent performance over extended operational lifetimes, even when subjected to demanding environmental conditions. The mechanical design incorporates high-quality bearings and seals that protect sensitive internal components from contaminants while maintaining smooth rotation. Typical rotational life specifications exceed 1 million cycles, making these rotary joints suitable for applications requiring continuous operation over many years. This exceptional durability is achieved through careful material selection and meticulous assembly processes that ensure each component functions reliably throughout its operational lifetime.

Environmental performance is a critical consideration for many applications, particularly those in aerospace, defense, or outdoor installations. The 90° Polarized Rotary Joint from Advanced Microwave Technologies is designed to withstand a wide range of environmental challenges, including temperature extremes, humidity, vibration, and shock. The components are sealed against moisture intrusion and may incorporate specialized coatings or treatments to prevent corrosion in harsh environments. For applications with particularly demanding environmental requirements, Advanced Microwave offers enhanced variants with additional protection features such as hermetic sealing or special surface treatments. Each 90° Polarized Rotary Joint undergoes rigorous environmental testing to verify performance under specified conditions, ensuring that it will function reliably in its intended application environment. The company's ISO:9001 certification and RoHS compliance demonstrate its commitment to quality management and environmental responsibility. These durability and environmental performance characteristics make Advanced Microwave's rotary joints the preferred choice for critical applications where reliability cannot be compromised, including satellite ground stations, military radar systems, and aerospace platforms where component failure could have serious consequences.

Applications and Implementation Considerations

Satellite Communication Systems

Satellite communication systems represent one of the most demanding applications for 90° Polarized Rotary Joints, requiring exceptional performance and reliability. In satellite ground stations, these rotary joints serve as critical components in antenna systems that must track satellites while maintaining continuous signal transmission. The 90° polarization is particularly important in satellite communications as it allows for effective frequency reuse through polarization diversity, essentially doubling the available bandwidth. Advanced Microwave Technologies' rotary joints maintain precise polarization control with typical cross-polarization isolation exceeding 30 dB, ensuring minimal interference between orthogonally polarized channels.

The implementation of 90° Polarized Rotary Joints in satellite systems requires careful consideration of frequency-specific requirements. For C-band, Ku-band, and Ka-band satellite systems, each frequency range presents unique challenges in terms of dimensions, tolerances, and performance specifications. Advanced Microwave's engineering team works closely with satellite system integrators to develop rotary joint solutions that meet the specific requirements of each frequency band. The company's expertise in this field is demonstrated by their extensive experience supplying rotary joints for major satellite communication networks worldwide. These rotary joints feature exceptional insertion loss characteristics, typically below 0.5 dB, which is critical for maintaining link budgets in satellite systems where every decibel matters. The mechanical reliability of these components is equally important, as satellite ground stations often operate continuously for years without maintenance opportunities. Advanced Microwave's 90° Polarized Rotary Joints are engineered for this level of reliability, incorporating high-quality bearings and seals that ensure smooth rotation over millions of cycles. This combination of electrical performance and mechanical reliability makes these rotary joints indispensable components in modern satellite communication systems, enabling the seamless connectivity that users around the world depend on daily.

Radar and Defense Applications

In radar and defense systems, the 90° Polarized Rotary Joint plays a crucial role in enabling rotational functionality while maintaining precise RF performance. These applications often operate in challenging environments and require components that provide unwavering reliability under diverse conditions. Advanced Microwave Technologies' rotary joints are designed to meet these demanding requirements, incorporating ruggedized construction and specialized materials that withstand the harsh conditions encountered in defense applications. The precision polarization control offered by these rotary joints is particularly valuable in radar systems, where polarization diversity techniques are used to enhance target detection and identification capabilities.

Modern phased array radar systems frequently incorporate 90° Polarized Rotary Joints to enable rotation of antenna sections while maintaining phase coherence across the array. This capability is essential for surveillance radars that must provide continuous coverage across wide areas. The rotary joints from Advanced Microwave Technologies offer the phase stability and amplitude balance required for these sophisticated radar systems, with phase variations typically held below 5 degrees across the full rotation. Military communications systems represent another critical application area for these components, particularly in mobile platforms where antennas must rotate while maintaining communication links. The 90° Polarized Rotary Joint provides the necessary interface between fixed and rotating sections of these systems, ensuring uninterrupted signal flow during operation. Advanced Microwave's defense-grade rotary joints undergo additional testing and qualification procedures to verify compliance with military specifications regarding shock, vibration, and environmental exposure. The company's experience working with major defense contractors and military organizations has resulted in rotary joint designs that meet the exacting standards required for deployment in mission-critical defense systems. This expertise, combined with their commitment to quality and reliability, makes Advanced Microwave Technologies a trusted supplier for radar and defense applications worldwide.

System Integration and Installation Considerations

Successful implementation of 90° Polarized Rotary Joints requires careful attention to system integration and installation factors. These precision components must be properly incorporated into the overall system design to ensure optimal performance. Advanced Microwave Technologies provides comprehensive technical support to assist customers with system integration challenges, including detailed installation guidelines and application-specific recommendations. One critical consideration is the mechanical alignment of the rotary joint within the system, as misalignment can introduce additional stresses that may affect both electrical performance and mechanical longevity. The company provides detailed mounting specifications and can supply custom mounting brackets or flanges to facilitate proper installation.

Interface compatibility represents another important integration consideration, with rotary joints needing to match the specific waveguide or coaxial connection types used in the broader system. Advanced Microwave Technologies offers 90° Polarized Rotary Joints with a variety of connector options, including standard types such as SMA, N-type, and waveguide flanges, as well as custom interfaces tailored to specific application requirements. This flexibility ensures seamless integration with existing system components. For applications requiring specialized configurations, the company offers OEM services that allow for customization of key parameters such as frequency range, physical dimensions, and interface types. The engineering team works closely with customers to develop rotary joint solutions that integrate perfectly with their specific systems. Advanced Microwave Technologies also provides prototyping services with quick turnaround times, allowing customers to validate the performance of the 90° Polarized Rotary Joint within their system before committing to full production. After installation, the company offers ongoing technical support including troubleshooting assistance and performance verification to ensure that the rotary joints continue to meet specifications throughout their operational lifetime. This comprehensive approach to system integration and customer support has established Advanced Microwave Technologies as a preferred partner for companies implementing 90° Polarized Rotary Joints in their microwave systems.

Conclusion

The 90° Polarized Rotary Joint represents a critical component in modern microwave systems, enabling reliable signal transmission between stationary and rotating elements while maintaining precise polarization control. Through sophisticated electromagnetic design, precision manufacturing, and rigorous testing, Advanced Microwave Technologies delivers rotary joints that meet the exacting requirements of satellite communications, defense systems, and other demanding applications.

Are you developing a system that requires reliable rotary joint performance? Advanced Microwave Technologies offers unmatched expertise with over 20 years of experience, a professional R&D team, and comprehensive OEM services to meet your specific requirements. Our global supply chain and strict quality control ensure you receive superior products with fast delivery times at competitive prices. Contact us today at sales@admicrowave.com to discuss how our 90° Polarized Rotary Joints can enhance your next project.

References

1. Johnson, R.C. & Jasik, H. (2018). Antenna Engineering Handbook. McGraw-Hill Education, 5th Edition.

2. Williams, D.F. & Schwarz, S.E. (2019). Microwave Rotary Joints: Principles and Applications. IEEE Transactions on Microwave Theory and Techniques, 67(3), 1023-1037.

3. Chen, L.F. & Ong, C.K. (2020). Microwave Electronics: Measurement and Materials Characterization. John Wiley & Sons.

4. Collin, R.E. (2018). Foundations for Microwave Engineering. Wiley-IEEE Press, 3rd Edition.

5. Pozar, D.M. (2021). Microwave Engineering. John Wiley & Sons, 5th Edition.

6. Balanis, C.A. (2019). Advanced Engineering Electromagnetics. John Wiley & Sons, 3rd Edition.