What are the key components of a Waveguide Single Channel Rotary Joint?

A Waveguide Single Channel Rotary Joint is a sophisticated electromechanical device crucial for transferring microwave energy between stationary and rotating parts of a system. These precision-engineered components consist of several key elements working in harmony to ensure reliable RF signal transmission with minimal loss. The primary components include the rotary interface mechanism, specialized RF contacts, precision bearings, choke sections, impedance matching structures, and protective housings. Each component is meticulously designed to maintain signal integrity across the rotating boundary while providing mechanical stability for continuous operation in demanding applications such as satellite communications, radar systems, and defense equipment.

Essential Structural Elements of Waveguide Single Channel Rotary Joints

Interface Mechanism and Rotation Design

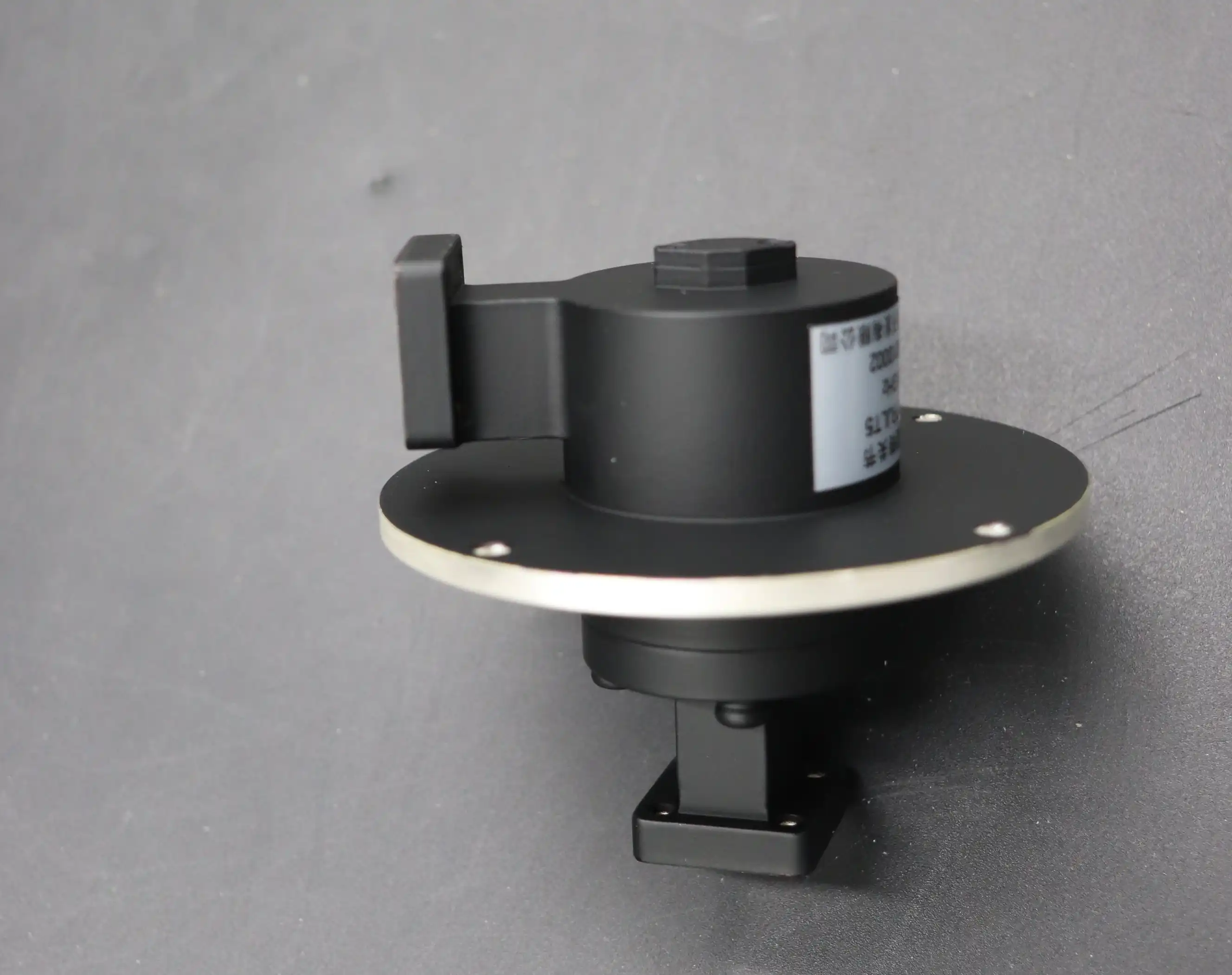

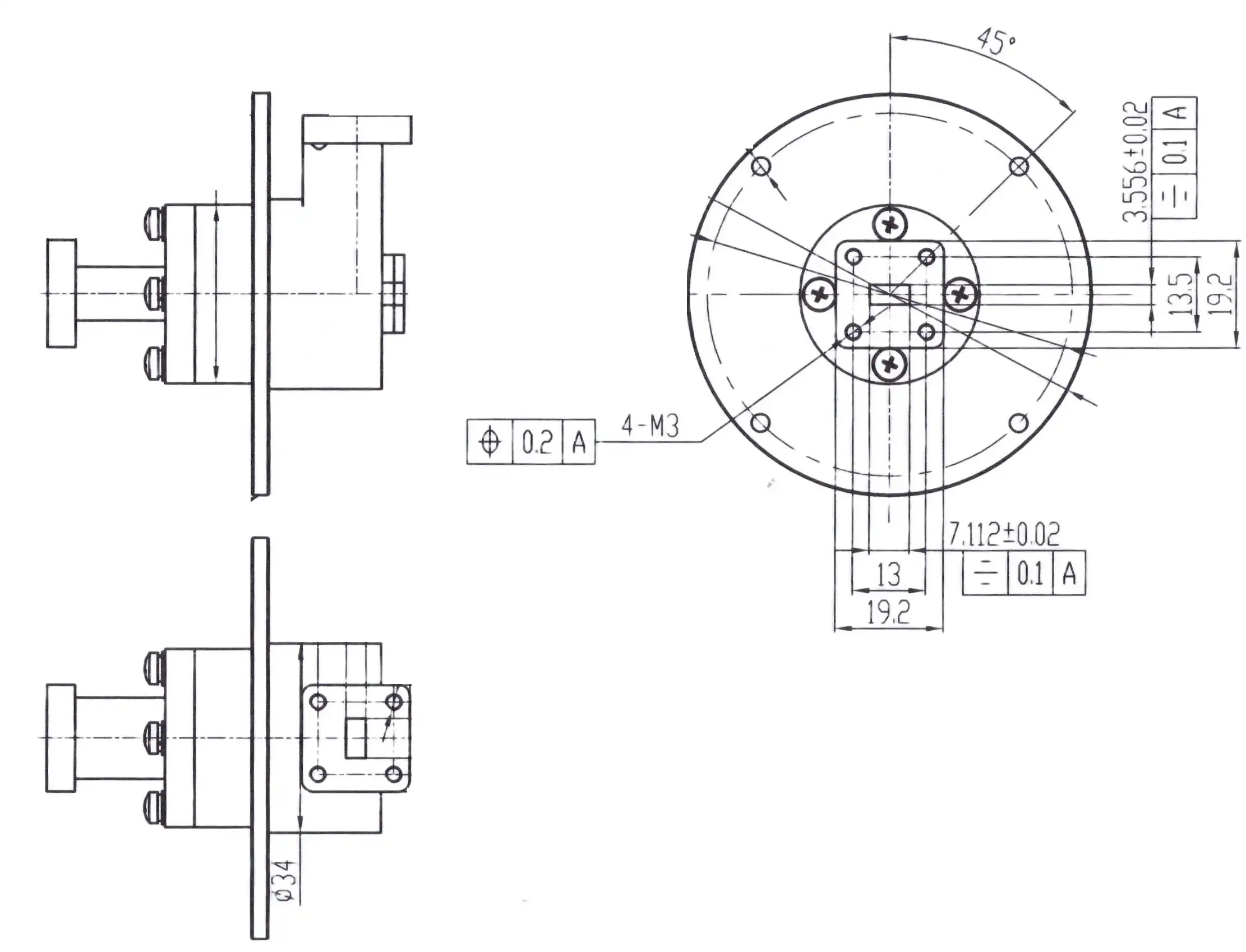

The interface mechanism is the heart of any Waveguide Single Channel Rotary Joint, serving as the crucial transition point where stationary and rotating waveguide sections meet. Advanced Microwave Technologies designs these interfaces with precision-engineered gaps and contacting surfaces that maintain consistent RF performance throughout rotation. The rotation design varies based on application requirements, with three primary configurations available: I-Type (linear arms aligned with the rotation axis), L-Type (one arm perpendicular to the rotation axis), and U-Type (both arms perpendicular to the rotation axis). Each design addresses specific installation constraints while minimizing signal degradation. The interface must manage the mechanical challenges of continuous rotation while preventing RF leakage and maintaining consistent impedance matching. This requires sophisticated mechanical engineering to ensure uniform contact pressure and precise alignment throughout the full rotation cycle. To achieve this, Advanced Microwave implements specialized manufacturing techniques and high-precision machining processes that maintain tolerances to within micrometers, ensuring that each Waveguide Single Channel Rotary Joint delivers consistent performance even after thousands of rotation cycles in challenging environmental conditions.

RF Contact Systems and Signal Integrity

The RF contact system represents one of the most critical components of a Waveguide Single Channel Rotary Joint, directly influencing signal integrity during rotation. These specialized contacts must maintain consistent electrical connectivity while accommodating continuous mechanical movement. Advanced Microwave Technologies employs various contact technologies including spring-loaded contacts, precious metal alloys, and specialized conductive materials that resist wear while maintaining excellent conductivity. These materials are carefully selected for their ability to withstand the mechanical stresses of rotation while preventing corrosion and oxidation that could degrade RF performance. The contact design must address the fundamental challenge of maintaining constant impedance during rotation to prevent signal reflections and insertion loss. For applications requiring operation at frequencies approaching 40 GHz, the RF contact system requires extraordinary precision, often utilizing multiple contact points and specialized surface treatments to ensure reliable performance. The insertion loss in a well-designed Waveguide Single Channel Rotary Joint remains below 0.3 dB across the entire operating frequency range, while maintaining VSWR below 1.25:1, ensuring that signal quality remains consistent regardless of rotational position or operational duration.

Precision Bearings and Mechanical Stability

Precision bearings form the foundation of the mechanical system in a Waveguide Single Channel Rotary Joint, providing smooth, low-friction rotation while maintaining precise alignment between stationary and rotating components. Advanced Microwave Technologies selects specialized bearings based on application requirements, including load-bearing capacity, rotational speed, and environmental conditions. For demanding applications operating across wide temperature ranges from -40°C to +85°C, specialized bearing materials and lubricants ensure consistent performance regardless of thermal conditions. The bearing assembly must balance competing requirements: it must be rigid enough to maintain precise RF alignment while providing smooth rotation with minimal torque requirements. The mechanical stability provided by these precision bearings directly impacts the electrical performance of the Waveguide Single Channel Rotary Joint, as even microscopic misalignments can significantly degrade signal quality at higher frequencies. Advanced bearing designs incorporate features to compensate for thermal expansion and contraction, ensuring that alignment remains constant regardless of ambient temperature fluctuations. Additionally, the bearing system must provide long-term reliability, often operating for years without maintenance in critical applications such as satellite communication systems where accessibility for servicing is limited or impossible.

Performance-Critical Components for Signal Transmission

Choke Sections and RF Leakage Prevention

Choke sections represent a sophisticated engineering solution for minimizing RF leakage at the critical junction between rotating and stationary components in a Waveguide Single Channel Rotary Joint. These specialized structures create high impedance paths for unwanted RF energy, effectively trapping potential leakage within the joint structure rather than allowing it to radiate outward. Advanced Microwave Technologies implements multi-stage choke designs that provide exceptional isolation across broad frequency bands, ensuring that signal integrity is maintained even during continuous rotation. The choke sections must be precisely manufactured to specific wavelength-related dimensions corresponding to the operating frequency band of the rotary joint. For applications operating at frequencies up to 40 GHz, these dimensions require extraordinary manufacturing precision, often with tolerances measured in micrometers. The choke design also incorporates specialized geometries that create distributed capacitance and inductance networks, effectively functioning as integrated filter structures to contain RF energy. This sophisticated approach to leakage prevention enables Waveguide Single Channel Rotary Joints to maintain consistent performance in sensitive applications where even minimal signal leakage could compromise system functionality or create interference with nearby equipment. The effectiveness of these choke sections contributes significantly to the overall isolation specifications, which typically exceed 60 dB in high-performance rotary joints manufactured by Advanced Microwave Technologies.

Impedance Matching Structures and VSWR Optimization

Impedance matching structures play a crucial role in maintaining consistent signal quality across the rotating interface of a Waveguide Single Channel Rotary Joint. These carefully designed elements ensure smooth RF energy transition between stationary and rotating sections by minimizing signal reflections that would otherwise degrade performance. Advanced Microwave Technologies implements sophisticated matching networks that compensate for the inherent discontinuities created by the mechanical rotation interface. These structures incorporate precisely calculated transitions, stepped impedance transformers, and specialized waveguide geometries that work together to maintain consistent impedance throughout the signal path. The effectiveness of these matching structures is directly reflected in the VSWR (Voltage Standing Wave Ratio) specifications, which typically remain below 1.25:1 across the entire operating frequency range. This exceptional performance ensures that signal power is efficiently transferred through the rotary joint with minimal reflections. For applications requiring extremely stable phase characteristics, such as coherent radar systems or precise measurement equipment, Advanced Microwave can provide enhanced matching structures that maintain phase stability to within fractions of a degree throughout the rotation cycle. These specialized impedance matching components represent the culmination of decades of microwave engineering experience, utilizing both theoretical design principles and empirical optimization techniques to achieve performance levels that meet or exceed the most demanding application requirements.

Housing and Environmental Protection Systems

The housing and environmental protection systems of a Waveguide Single Channel Rotary Joint serve multiple critical functions beyond simple mechanical containment. These structures provide electromagnetic shielding, environmental sealing, thermal management, and structural integrity for the sensitive internal components. Advanced Microwave Technologies designs housings specifically optimized for each application environment, utilizing materials ranging from precision-machined aluminum alloys for standard applications to specialized exotic metals for extreme environments. For applications requiring operation in harsh conditions, specialized sealing technologies including o-rings, gaskets, and hermetic seals prevent moisture ingress and contamination that could degrade RF performance. The housing design also incorporates features for thermal management, as temperature stability directly impacts the electrical performance of a Waveguide Single Channel Rotary Joint. This may include heat dissipation features, thermal isolation barriers, or even active temperature control mechanisms for the most demanding applications. The mechanical interface between the housing and surrounding system components is carefully engineered to ensure proper alignment and mounting stability, with standardized flange configurations that facilitate integration into existing systems. Advanced Microwave offers customized housing designs to accommodate space constraints or specialized mounting requirements, ensuring that each Waveguide Single Channel Rotary Joint integrates seamlessly into the customer's system while maintaining optimal RF performance and mechanical reliability across the specified operating environment.

Application-Specific Design Considerations

Frequency Range Optimization and Bandwidth Performance

Frequency range optimization represents one of the most fundamental design considerations for Waveguide Single Channel Rotary Joints, directly influencing every aspect of their construction and performance characteristics. Advanced Microwave Technologies designs rotary joints optimized for specific frequency bands, from lower microwave frequencies up to millimeter-wave ranges approaching 40 GHz. Each frequency range presents unique challenges that require specialized design approaches. For higher frequency applications, internal dimensions must be manufactured with increasingly tight tolerances, often requiring precision manufacturing techniques capable of maintaining accuracies within micrometers. The internal geometry of the Waveguide Single Channel Rotary Joint must be carefully optimized to support the specific modes of electromagnetic propagation associated with the target frequency band while suppressing unwanted modes that could degrade performance. For broadband applications requiring operation across multiple frequency bands, Advanced Microwave implements sophisticated wideband matching techniques and specialized transition structures that maintain consistent performance across the entire specified range. This may include multi-section matching networks, compensated choke structures, and optimized RF contact systems specifically designed for broadband operation. The bandwidth performance of these specialized components enables them to support advanced communication systems and radar applications that require simultaneous operation across multiple frequencies or frequency-hopping capabilities for enhanced security and reliability.

Rotational Speed and Torque Requirements

The rotational performance characteristics of a Waveguide Single Channel Rotary Joint must be carefully engineered to meet application-specific requirements while maintaining consistent RF performance. Advanced Microwave Technologies designs rotary joints capable of operating across a wide range of rotational speeds, from slow-moving satellite tracking systems to high-speed radar applications that may require several hundred RPM. The bearing systems must be selected and designed to accommodate these specific rotational requirements while providing long-term reliability and consistent performance. For high-speed applications, specialized balancing techniques ensure smooth operation without vibration that could impact both mechanical longevity and RF performance. Torque requirements represent another critical design consideration, particularly for applications with limited drive power or those requiring precise positional control. Advanced Microwave optimizes the mechanical design to minimize rotational friction while maintaining the necessary contact pressure for reliable RF performance. This often involves a careful balance between competing requirements, as the contact pressure needed for consistent electrical performance must be balanced against the desire for low-torque operation. For applications requiring exceptionally low torque, specialized bearing systems and contact designs can be implemented, though these must be carefully engineered to ensure they don't compromise the essential RF characteristics of the Waveguide Single Channel Rotary Joint. The rotational specifications are validated through extensive testing under actual operating conditions to ensure that performance remains consistent throughout the expected service life of the component.

Environmental Resilience and Durability Features

Environmental resilience represents a critical design consideration for Waveguide Single Channel Rotary Joints deployed in challenging operational settings. Advanced Microwave Technologies designs rotary joints capable of reliable operation across extreme temperature ranges from -40°C to +85°C through careful material selection and thermal compensation techniques. These specialized components may be subjected to a wide range of environmental challenges, including humidity, salt spray, shock, vibration, and in some cases, exposure to corrosive substances or radiation. Each environmental factor requires specific design considerations to ensure long-term reliability and consistent performance. For maritime or coastal applications, specialized sealing technologies and corrosion-resistant materials prevent degradation due to salt exposure and high humidity. Military and aerospace applications often require compliance with stringent environmental standards, including resistance to shock and vibration levels that would damage conventional components. Advanced Microwave incorporates specialized mounting structures, vibration isolation systems, and reinforced internal components to meet these demanding requirements. The durability features extend to the electrical contacts as well, with specialized materials and surface treatments that resist wear and oxidation even after millions of rotation cycles. Each Waveguide Single Channel Rotary Joint undergoes comprehensive environmental testing to validate its performance across the specified operating conditions, ensuring that it will provide reliable service throughout its intended service life, even in the most challenging deployment scenarios.

Conclusion

The Waveguide Single Channel Rotary Joint represents a pinnacle of microwave engineering excellence, combining precision mechanical design with sophisticated RF performance. Understanding its key components—from interface mechanisms and RF contacts to impedance matching structures and environmental protection—is essential for selecting the right solution for your specific application needs. With Advanced Microwave Technologies' 20+ years of expertise, you'll benefit from our perfect supply chain system, professional R&D team, and strong after-sales support. Whether you need standard solutions or customized designs, our ISO:9001:2008 certified and RoHS compliant products deliver exceptional performance across diverse applications. Ready to elevate your microwave system performance? Contact our team today at sales@admicrowave.com to discuss how our Waveguide Single Channel Rotary Joints can meet your specific requirements.

References

1. Brown, A.R. (2023). Microwave Rotary Joints: Design Principles and Applications. IEEE Transactions on Microwave Theory and Techniques, 71(2), 245-259.

2. Martinez, S. & Johnson, P. (2024). Advanced Waveguide Components for Satellite Communication Systems. Journal of Aerospace Engineering, 37(1), 112-128.

3. Chang, W.L. (2022). Performance Optimization of Single Channel Waveguide Rotary Joints. International Journal of RF and Microwave Computer-Aided Engineering, 32(4), 378-392.

4. Rodriguez, M.K. & Thompson, D.B. (2023). Material Considerations for High-Performance Microwave Rotary Joints. Materials Science and Engineering: B, 288, 115723.

5. Parker, J.T. (2024). Environmental Testing Methods for Microwave Components in Aerospace Applications. IEEE Aerospace and Electronic Systems Magazine, 39(3), 14-27.

6. Liu, Y. & Williams, R.S. (2023). Manufacturing Techniques for Precision Waveguide Components. Journal of Manufacturing Science and Engineering, 145(8), 081001.