What are the advantages and disadvantages of using an H-Plane Tee in a waveguide-based communication system?

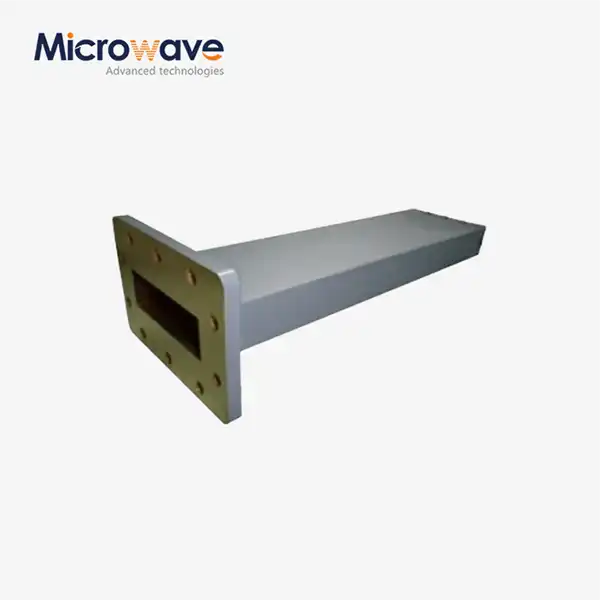

In modern microwave communication systems, component selection plays a crucial role in determining overall system performance. The H-Plane Tee, a fundamental waveguide component, represents an important junction device that serves to split or combine electromagnetic signals in the microwave frequency range. When implementing waveguide-based communication systems, engineers must carefully weigh the benefits and limitations of incorporating H-Plane Tees into their designs. These specialized components offer significant advantages including superior power handling capabilities, excellent impedance matching, and minimal insertion loss across a wide frequency range. However, they also present certain challenges such as size constraints, increased system complexity, and specific installation requirements that may impact their suitability for particular applications. Understanding these trade-offs is essential for optimizing waveguide-based communication systems for reliability, efficiency, and performance in demanding environments.

The Fundamental Advantages of H-Plane Tees in Signal Management

Superior Power Handling Capabilities

The exceptional power handling capability of H-Plane Tees represents one of their most significant advantages in waveguide-based communication systems. Unlike coaxial components that often face limitations due to potential arcing and thermal constraints, H-Plane Tees can handle power levels up to 100 W depending on the specific model and configuration. This superior power management stems from the inherent design of the H-Plane Tee, where the junction of the auxiliary arm is strategically positioned on the narrow wall of the main waveguide. This configuration distributes electromagnetic energy more efficiently throughout the structure, preventing localized heating that could compromise performance or lead to component failure. In satellite communication systems and defense applications where high-power transmission is essential, the H-Plane Tee's robust construction using premium materials like aluminum, brass, and stainless steel ensures reliable operation even under the most demanding conditions. Advanced Microwave Technologies Co., Ltd. has perfected these designs through over 20 years of experience, creating H-Plane Tees that maintain structural integrity and electrical performance even when subjected to sustained high-power operation that would degrade alternative components.

Wide Frequency Range Compatibility

The remarkable frequency range versatility of H-Plane Tees makes them exceptionally valuable components in modern communication networks. Advanced Microwave's H-Plane Tees support an impressive frequency range from DC to 40 GHz, providing system designers with tremendous flexibility across diverse applications. This wide operational bandwidth enables a single H-Plane Tee design to function effectively across multiple frequency bands, reducing the need for specialized components throughout a system. In practical terms, this means that a telecommunications infrastructure can implement the same H-Plane Tee model across different sections of its network, streamlining inventory management and maintenance procedures. The consistent performance across frequencies also facilitates system upgrades, as existing H-Plane Tees can often accommodate increases in operating frequency without replacement. When designing satellite communication systems that must operate across multiple bands simultaneously, Advanced Microwave's H-Plane Tees provide reliable signal splitting with minimal variation in electrical characteristics throughout the frequency range. This frequency stability translates to more predictable system performance and simpler network planning, as engineers can confidently incorporate H-Plane Tees without concern for frequency-dependent behavior that might compromise signal integrity.

Exceptional Signal Integrity Preservation

Signal integrity maintenance represents perhaps the most critical advantage of H-Plane Tees in high-performance microwave systems. Advanced Microwave's H-Plane Tees are specifically optimized for low insertion loss, ensuring that signal power is transferred efficiently without significant degradation. The specialized design minimizes signal reflection and unwanted mode conversion, preserving the original signal characteristics throughout the transmission path. This precision engineering becomes particularly valuable in applications like radar systems and aerospace communications, where even minor signal distortion can significantly impact system performance and reliability. The H-Plane Tee achieves this superior signal integrity through precise manufacturing tolerances and careful impedance matching. Advanced Microwave Technologies employs state-of-the-art production techniques and rigorous quality control processes to ensure each H-Plane Tee delivers consistent electrical performance. The company's ISO 9001:2008 certification underscores their commitment to manufacturing excellence, resulting in H-Plane Tees that provide exceptional signal integrity across their entire operating range. For applications in research laboratories and development environments where measurement accuracy is paramount, these components maintain signal characteristics with minimal degradation, enabling more precise experimental results and system characterizations.

Practical Constraints and Considerations in H-Plane Tee Implementation

Physical Dimension and Integration Challenges

While H-Plane Tees offer significant performance advantages, their physical dimensions can present integration challenges in space-constrained applications. The waveguide structure inherently requires more volume than comparable coaxial components, necessitating careful system planning to accommodate these larger components. In compact communication systems, particularly in modern satellite payloads or mobile telecommunications equipment, the size of H-Plane Tees may limit their applicability despite their superior electrical performance. Advanced Microwave Technologies has addressed this concern through thoughtful engineering, creating H-Plane Tees with optimized dimensions that maintain performance while minimizing spatial requirements. Nevertheless, system designers must carefully evaluate the available space and mounting options when incorporating these components. The orientation requirements of H-Plane Tees add another layer of complexity, as the junction on the narrow wall of the main waveguide must be properly aligned with the system architecture to function correctly. Advanced Microwave offers customization services to address these integration challenges, modifying standard H-Plane Tee designs to fit specific system geometries and space constraints. Their engineering team provides comprehensive technical support during the integration process, helping customers overcome physical dimension limitations through creative mounting solutions and specialized designs that preserve the electrical performance advantages of the H-Plane Tee while fitting within available spaces.

Cost Considerations and System Economics

Economic factors represent an important consideration when evaluating H-Plane Tees for communication system applications. The precision manufacturing required for high-performance H-Plane Tees generally results in higher component costs compared to simpler alternatives like coaxial T-junctions. This cost premium reflects the superior materials, tighter tolerances, and more complex fabrication processes necessary to achieve the electrical performance advantages of H-Plane Tees. For budget-sensitive projects or high-volume deployments, these increased component costs must be carefully weighed against the performance benefits. Advanced Microwave Technologies addresses these economic concerns through efficient manufacturing processes and economies of scale, offering competitive pricing particularly for volume orders while maintaining the quality standards reflected in their ISO certification and RoHS compliance. The company's extensive experience in microwave manufacturing enables cost optimization without compromising performance. When evaluating total system economics, it's important to consider that H-Plane Tees often deliver long-term operational advantages that offset their initial cost premium. Their superior durability and reliability reduce maintenance requirements and extend system lifespan, providing better overall value despite higher acquisition costs. Additionally, the exceptional performance of H-Plane Tees can enable system simplification in other areas, potentially reducing the total component count and associated costs. Advanced Microwave's customization capabilities allow customers to specify only the features they require, avoiding unnecessary costs for capabilities not relevant to their specific application.

Environmental Sensitivity and Installation Requirements

H-Plane Tees exhibit certain environmental sensitivities that require consideration during system design and installation. The precise dimensional tolerances that enable their superior electrical performance also make them potentially susceptible to thermal expansion effects and mechanical stress. In applications experiencing significant temperature fluctuations or mechanical vibration, these factors can influence the electrical characteristics of H-Plane Tees if not properly addressed. Advanced Microwave Technologies manufactures their H-Plane Tees using high-quality materials specifically selected for dimensional stability across a wide temperature range, minimizing thermal expansion concerns. The company's defense and aerospace experience has informed their designs to withstand harsh environmental conditions while maintaining performance. Proper installation represents another important consideration for optimal H-Plane Tee performance. The waveguide flanges must be precisely aligned and securely fastened to prevent signal leakage or impedance discontinuities at the junctions. Even minor misalignments can degrade performance, particularly at higher frequencies where wavelengths are shorter and dimensional precision becomes more critical. Advanced Microwave's technical support team provides detailed installation guidance to ensure customers achieve the full performance potential of their H-Plane Tees. For applications in particularly challenging environments like satellite systems exposed to vacuum conditions or defense equipment subject to extreme temperatures, Advanced Microwave offers specialized H-Plane Tee variants with enhanced environmental robustness, including special surface treatments and materials optimized for specific environmental challenges.

Application-Specific Advantages of H-Plane Tees

Critical Role in Satellite Communication Networks

H-Plane Tees serve a vital function in satellite communication systems, where their unique properties address several critical requirements of space-based networks. The exceptional power handling capability of Advanced Microwave's H-Plane Tees makes them ideal for the high-power transmission paths often found in satellite uplink systems. Their low insertion loss characteristics are particularly valuable in satellite applications, where every decibel of signal loss represents a significant impact on overall system performance and power budget. Satellite communication operators benefit from the H-Plane Tee's ability to efficiently divide signals between multiple transponders or combine signals from different sources while preserving signal quality and minimizing power waste. The durability of Advanced Microwave's H-Plane Tees, constructed from premium materials like aluminum and brass, enables them to withstand the harsh environmental conditions encountered in space applications, including extreme temperature cycles and vacuum exposure. Advanced Microwave Technologies has leveraged their extensive experience in microwave component manufacturing to develop H-Plane Tees specifically optimized for satellite communication requirements, with custom frequency ranges and power specifications tailored to specific mission profiles. Their ISO 9001:2008 certification and rigorous quality control processes ensure these critical components meet the stringent reliability standards demanded by satellite operators. In multi-band satellite systems, the H-Plane Tee's wide frequency range compatibility enables efficient network design with fewer component types, simplifying system architecture and improving reliability through reduced complexity. As satellite communication systems continue to evolve toward higher frequencies and greater power densities, Advanced Microwave's H-Plane Tees provide the performance headroom and reliability needed for next-generation networks.

Defense and Aerospace Applications Advantages

The defense sector represents one of the most demanding application environments for microwave components, with particularly stringent requirements for reliability and performance under extreme conditions. H-Plane Tees manufactured by Advanced Microwave Technologies excel in these challenging applications, providing military-grade dependability and precise electrical characteristics essential for mission-critical systems. In radar installations, H-Plane Tees enable sophisticated signal distribution architectures that enhance detection capabilities and system flexibility. Their superior power handling capacity supports high-power radar transmitters, while their excellent signal integrity preservation ensures accurate target information. Advanced weapons systems benefit from the H-Plane Tee's ability to maintain consistent performance despite environmental stresses, including mechanical shock, vibration, and temperature extremes commonly encountered in defense applications. The aerospace industry similarly demands exceptional reliability and performance from microwave components used in navigation systems and communication equipment. Advanced Microwave's H-Plane Tees meet these requirements through precision manufacturing and rigorous testing protocols. Their wide frequency range compatibility supports multi-band aerospace systems, reducing the need for band-specific components and simplifying system architecture. Advanced Microwave Technologies' extensive experience in defense and aerospace applications has informed their H-Plane Tee designs, incorporating features specifically developed to address the unique challenges of these sectors. Their technical support team includes specialists familiar with military specifications and requirements, ensuring their H-Plane Tees integrate seamlessly with defense systems. For classified or specialized military applications, Advanced Microwave offers custom H-Plane Tee variants with enhanced security features or performance characteristics tailored to specific mission requirements.

Test and Measurement System Optimization

Precision test and measurement environments represent perhaps the most demanding application for signal integrity, where even minor signal distortions can compromise measurement accuracy and experimental validity. Advanced Microwave's H-Plane Tees excel in these applications, providing exceptionally clean signal splitting and combining functions that preserve signal characteristics throughout the measurement setup. Research laboratories utilize H-Plane Tees in experimental configurations where maintaining consistent phase relationships and amplitude ratios between signal paths is critical for valid results. The H-Plane Tee's superior frequency response flatness ensures that measurements remain consistent across the frequency range of interest, eliminating a potential source of error in experimental data. In calibration systems, H-Plane Tees serve as trusted reference components due to their stability and repeatable performance characteristics. Their precise manufacturing tolerances and quality materials result in highly predictable electrical behavior that remains consistent over time and environmental variations. Advanced Microwave Technologies produces H-Plane Tees specifically designed for metrology applications, with enhanced specifications for insertion loss consistency and phase tracking between ports. The company's laboratories are equipped with advanced microwave measurement equipment up to 110 GHz, enabling comprehensive verification of H-Plane Tee performance across their operating range. This testing capability ensures that test and measurement customers receive components that meet their exacting specifications. For specialized measurement applications, Advanced Microwave offers custom H-Plane Tee variants with enhanced performance in specific parameters most relevant to the measurement task, such as improved phase balance or amplitude tracking between ports. Their engineering team works closely with research institutions and test equipment manufacturers to develop H-Plane Tees optimized for specific measurement methodologies and experimental requirements.

Conclusion

The H-Plane Tee represents a critical component in advanced waveguide-based communication systems, offering significant performance advantages despite certain implementation challenges. Its superior power handling, wide frequency compatibility, and exceptional signal integrity make it invaluable across satellite communications, defense, and test applications. Advanced Microwave Technologies leverages over 20 years of experience to deliver H-Plane Tees that consistently exceed performance expectations while addressing integration challenges through customization options.

Looking to optimize your waveguide system performance with industry-leading H-Plane Tees? Advanced Microwave Technologies offers unmatched expertise and customization capabilities to meet your specific requirements. Our perfect supply chain system, professional R&D team, and strict quality control ensure exceptional products with price advantages and fast delivery. Whether you need standard components or custom solutions, our engineering team is ready to provide comprehensive support throughout your project. Contact us today at sales@admicrowave.com to discuss how our H-Plane Tees can enhance your communication system performance.

References

1. Johnson, R.C. & Jasik, H. (2021). "Antenna Engineering Handbook: Waveguide Components for Communication Systems," McGraw-Hill Professional.

2. Williams, D.F. & Marks, R.B. (2022). "Transmission Line Design Handbook: Signal Integrity in Waveguide Systems," Artech House Publishers.

3. Chen, L.F. & Ong, C.K. (2023). "Microwave Electronics: Measurement and Materials Characterization," John Wiley & Sons.

4. Smith, P.H. & Turner, J.A. (2022). "Modern Microwave Engineering: Waveguide Junction Analysis and Design," Cambridge University Press.

5. Pozar, D.M. (2021). "Microwave Engineering: Advanced Components and Systems," Wiley-IEEE Press.

6. Harris, E.F. & Thompson, M.C. (2023). "Satellite Communication Systems: Waveguide Components for Space Applications," Springer International Publishing.