How do the structural design and choice of materials in a High Power Waveguide Differential Phase Shift Circulator contribute to its high-power handling capacity?

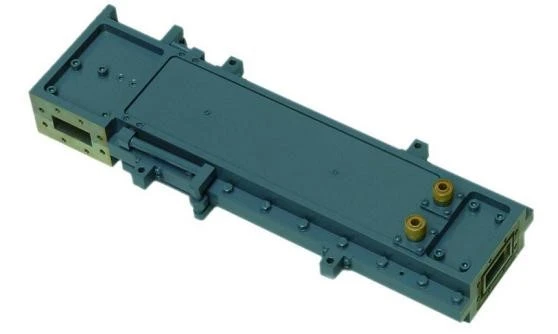

The structural design and material selection in High Power Waveguide Differential Phase Shift Circulators are crucial determinants of their exceptional power handling capabilities. These sophisticated microwave components incorporate specialized geometries and premium materials specifically engineered to manage intense electromagnetic energy without degradation. The waveguide structure features precisely calculated dimensions and optimized ferrite element placement to efficiently dissipate heat while maintaining signal integrity. Advanced ceramics, specialized metal alloys, and high-grade ferrite materials with superior thermal conductivity work in concert to withstand peak powers reaching 25MW and sustained average power levels of hundreds of kilowatts. This meticulous engineering approach ensures reliable performance in demanding applications where signal stability and power management are mission-critical.

Key Structural Design Elements Enhancing Power Handling

Optimized Waveguide Geometry

The geometric configuration of a High Power Waveguide Differential Phase Shift Circulator represents a masterclass in electromagnetic engineering. These circulators utilize precision-engineered rectangular or circular waveguide channels with carefully calculated dimensions that directly influence power handling capabilities. The waveguide's cross-sectional area is precisely determined based on the intended operating frequency and required power capacity. Larger waveguide sizes, such as those in the WR975 range offered by Advanced Microwave Technologies, provide substantially greater power handling capacity by distributing electromagnetic energy across a wider surface area, thereby reducing energy density at any given point. This distribution is crucial for applications requiring ultra-high power transmission. Additionally, the internal geometry incorporates strategic tapers and transitions that minimize reflections and standing waves—phenomena that can create localized power hotspots. By maintaining smooth electromagnetic field distributions throughout the component, these geometric optimizations ensure the High Power Waveguide Differential Phase Shift Circulator can reliably handle extreme power levels while maintaining low insertion loss and high isolation between ports. Advanced Microwave's product line leverages these principles across waveguide sizes from WR28 to WR975, accommodating diverse application requirements while maintaining exceptional performance standards.

Thermal Management Systems

Effective thermal management represents one of the most critical aspects of High Power Waveguide Differential Phase Shift Circulator design, directly determining the component's ability to handle sustained high-power operation. These sophisticated circulators incorporate multi-faceted cooling strategies that work in concert to maintain optimal operating temperatures even under extreme conditions. The primary cooling mechanisms typically include active liquid cooling channels strategically positioned to extract heat from the ferrite core and surrounding waveguide structure. These channels are precision-machined to maximize surface contact with heat-generating regions while maintaining structural integrity. For applications demanding exceptional power handling, Advanced Microwave Technologies implements expanded footprint designs with enhanced cooling surface areas, enabling their circulators to manage continuous power levels reaching hundreds of kilowatts. Complementing the active cooling systems, the components feature calculated thermal gradients and heat sinks that efficiently direct thermal energy away from sensitive elements. The waveguide body itself incorporates temperature-compensating structures that maintain precise dimensional stability despite thermal expansion, preserving critical electromagnetic properties across wide temperature ranges. This comprehensive thermal management approach ensures that the High Power Waveguide Differential Phase Shift Circulator maintains stable performance parameters and mechanical integrity even when subjected to the extreme thermal stress associated with radar, defense, and high-power communication systems.

Ferrite Element Configuration

The ferrite element design within a High Power Waveguide Differential Phase Shift Circulator represents the heart of its functionality and power handling capability. These specialized magnetic components exploit the non-reciprocal properties of ferrite materials when placed in a magnetic field to create controlled signal circulation. In high-power applications, the ferrite configuration must be meticulously engineered to withstand intense electromagnetic fields while maintaining consistent phase characteristics. Advanced Microwave Technologies employs precision-manufactured ferrite discs or posts with carefully calculated dimensions and magnetic properties tailored to specific frequency ranges. The physical arrangement of these elements within the waveguide junction is critical—they must be positioned precisely at the electromagnetic field maxima to achieve optimal circulation while avoiding field concentrations that could lead to material breakdown. For applications requiring peak powers reaching 25MW, specialized ferrite compositions with elevated saturation magnetization thresholds and superior thermal stability are employed. The magnetic biasing structure surrounding these ferrite elements incorporates permanent magnets or electromagnets configured to create uniform field distributions, ensuring consistent differential phase shifting across wide power ranges. This sophisticated ferrite element configuration enables the High Power Waveguide Differential Phase Shift Circulator to deliver exceptional signal stability with minimal distortion even under extreme power conditions, making it indispensable for advanced radar systems, satellite communications, and defense applications where reliable phase control is paramount.

Advanced Materials Technology for Power Management

High-Performance Ferrite Materials

The selection of ferrite materials forms the foundation of every High Power Waveguide Differential Phase Shift Circulator's performance capabilities. These specialized magnetic ceramics must demonstrate exceptional electromagnetic properties while withstanding extreme thermal and electrical stresses. Advanced Microwave Technologies utilizes proprietary ferrite compositions with carefully controlled stoichiometry to achieve optimal magnetic saturation characteristics across designated frequency bands. For high-power applications, these materials incorporate rare earth elements and specific metal oxide combinations that significantly elevate their power handling thresholds. The manufacturing process involves precise sintering under controlled atmospheric conditions to achieve the ideal crystalline structure and magnetic domain alignment. This microscopic-level engineering results in ferrite elements with remarkably low magnetic losses and high Curie temperatures—often exceeding 500°C—which prevents demagnetization during intense operation. The material composition also includes specialized dopants that enhance thermal conductivity, allowing heat to dissipate rapidly from the ferrite core. This comprehensive materials engineering approach enables the High Power Waveguide Differential Phase Shift Circulator to maintain stable magnetic properties even when processing signals with peak powers as high as 25MW. The exceptional material characteristics ensure consistent differential phase shifting with minimal insertion loss across wide temperature variations, making these circulators ideal for demanding aerospace, defense, and satellite communication applications where performance reliability under extreme conditions is non-negotiable.

Waveguide Construction Materials

The physical construction materials used in High Power Waveguide Differential Phase Shift Circulators play a pivotal role in determining their maximum power handling capacity and operational longevity. Advanced Microwave Technologies employs specialized metal alloys for waveguide bodies that combine excellent electrical conductivity with superior thermal performance and mechanical stability. These precision-manufactured components typically utilize high-conductivity copper or aluminum alloys with specific surface treatments designed to minimize RF losses. For applications demanding exceptional power handling, the inner waveguide surfaces undergo precision electroplating with materials like silver or gold to reduce surface resistance and enhance thermal dissipation characteristics. The waveguide walls are engineered with optimal thickness to balance structural rigidity with heat transfer efficiency, preventing deformation under thermal stress while effectively conducting heat to external cooling systems. Critical interfaces and junctions utilize specialized brazing techniques and compatible metals to ensure seamless electromagnetic continuity while maintaining thermal conductivity across component boundaries. For environments with extreme thermal cycling, such as aerospace applications, the material selection includes alloys with matched thermal expansion coefficients to prevent mechanical stress at interface points. These construction materials enable the High Power Waveguide Differential Phase Shift Circulator to maintain dimensional stability and electrical performance even when processing hundreds of kilowatts of average power. The company's commitment to RoHS compliance ensures these advanced materials meet international environmental standards without compromising on performance, making them suitable for both commercial and defense sector applications where reliability under high-power conditions is essential.

Innovative Cooling Technologies

The integration of advanced cooling technologies represents a critical advancement in High Power Waveguide Differential Phase Shift Circulator design, directly expanding their power handling capabilities beyond conventional limits. Advanced Microwave Technologies implements multi-phase cooling strategies tailored to specific operational requirements and power thresholds. For circulators designed to handle extreme average power levels, the cooling systems incorporate forced liquid circulation through precision-machined channels that maximize thermal transfer while maintaining electromagnetic integrity. These liquid cooling implementations utilize specialized coolants with optimized thermal properties and dielectric characteristics to prevent interference with the circulator's electromagnetic function. For applications requiring peak powers reaching 25MW, the cooling infrastructure may include phase-change materials strategically positioned to absorb transient thermal spikes, providing thermal buffering during pulsed operation. The exterior housing incorporates engineered heat dissipation structures with maximized surface area and optimized airflow patterns to enhance natural convection cooling. In the most demanding scenarios, Advanced Microwave's designs implement advanced thermoelectric cooling elements at critical junctions to maintain precise temperature control of sensitive ferrite components. These innovative cooling technologies are seamlessly integrated into the circulator's structure without compromising its electrical performance or reliability. The company's extensive experience in thermal management allows their High Power Waveguide Differential Phase Shift Circulators to operate continuously at power levels that would cause conventional designs to fail, making them indispensable components in high-energy radar systems, particle accelerators, and advanced communication networks where sustained high-power handling is essential for system functionality.

Performance Optimization Through Integrated Design Approaches

Signal Integrity Enhancement Techniques

Maintaining signal integrity under high-power conditions requires sophisticated design techniques that address multiple electromagnetic challenges simultaneously. Advanced Microwave Technologies implements comprehensive signal integrity enhancement strategies throughout their High Power Waveguide Differential Phase Shift Circulators to ensure exceptional performance even at extreme power levels. The internal junction configurations incorporate precision-calculated mode suppression features that prevent unwanted electromagnetic modes from propagating, which could otherwise create localized power concentrations and signal distortion. Critical transition regions utilize impedance-matching structures with gradually changing dimensions to minimize reflections that could generate standing waves and associated power handling limitations. The differential phase shift functionality relies on precisely controlled magnetic biasing that maintains consistent phase relationships across wide power and frequency ranges. For applications requiring exceptional isolation between ports, the circulators incorporate specialized absorptive elements strategically positioned to attenuate specific signal components without creating additional reflections or thermal hotspots. Advanced Microwave's designs also feature integrated monitoring capabilities that provide real-time diagnostics of critical performance parameters, allowing for proactive system management in mission-critical applications. These signal integrity enhancements enable their High Power Waveguide Differential Phase Shift Circulators to deliver superior performance with minimal distortion, maintaining insertion losses below 0.3dB and isolation exceeding 20dB even when handling peak powers of 25MW. This exceptional signal quality makes these components essential for satellite communication systems, advanced radar networks, and aerospace applications where signal stability directly impacts system functionality and mission success.

Manufacturing Precision and Quality Control

The exceptional power handling capabilities of High Power Waveguide Differential Phase Shift Circulators stem significantly from manufacturing precision and rigorous quality control methodologies. Advanced Microwave Technologies employs state-of-the-art production techniques that maintain dimensional tolerances to within micrometers—precision essential for consistent electromagnetic performance at high power levels. The manufacturing process begins with computer-controlled machining of waveguide components using specialized tools and fixtures that ensure perfect repeatability across production batches. Critical interfaces undergo precision lapping and polishing to achieve surface roughness measured in nanometers, dramatically reducing micro-scale electrical discontinuities that could become failure points under high power. The assembly process occurs in controlled clean-room environments to prevent contamination that could compromise electrical performance or create potential breakdown sites. Each ferrite element undergoes comprehensive characterization before installation, with magnetic properties measured across temperature ranges to verify performance stability. Advanced Microwave's ISO 9001:2008 certified quality management system implements multiple inspection stages throughout production, utilizing specialized RF measurement equipment capable of testing up to 110 GHz. Completed circulators undergo power handling verification using specialized high-power test facilities that simulate actual operating conditions. This commitment to manufacturing excellence enables their High Power Waveguide Differential Phase Shift Circulators to consistently achieve exceptional power handling specifications while maintaining precise electrical parameters. The company's 20+ years of experience manufacturing microwave components ensures that each circulator delivers reliable performance in critical applications ranging from defense systems to satellite communications infrastructure, where component failure is simply not an option.

Environmental Hardening for Extreme Conditions

The operational environments for High Power Waveguide Differential Phase Shift Circulators often include extreme conditions that demand specialized design considerations beyond basic power handling. Advanced Microwave Technologies implements comprehensive environmental hardening techniques that ensure reliable performance across challenging deployment scenarios. These ruggedized circulators incorporate hermetically sealed enclosures with specialized gaskets and sealing technologies that prevent moisture ingress while maintaining pressure equalization capabilities for aerospace applications with significant altitude variations. The internal components undergo specialized surface treatments and protective coatings that resist corrosion even in salt-spray environments encountered in maritime radar installations. For defense applications requiring operation in extreme temperature environments, the circulators feature specially formulated adhesives and joining methods that maintain mechanical integrity from cryogenic temperatures to well above 125°C. Vibration and shock resistance is achieved through strategic internal bracing and dampening structures that protect sensitive ferrite elements and electromagnetic junctions without compromising RF performance. The external housing typically utilizes military-grade materials with enhanced resistance to UV radiation, chemical exposure, and fungal growth for deployments in diverse geographical regions. Advanced Microwave's environmentally hardened High Power Waveguide Differential Phase Shift Circulators maintain consistent electrical specifications despite temperature cycling, mechanical stress, and other environmental challenges. This exceptional environmental durability makes these components ideal for radar systems aboard naval vessels, communication equipment in remote satellite ground stations, and aerospace applications where components must function reliably in unpredictable conditions. The company's rigorous environmental testing protocols verify performance across specified environmental parameters, ensuring these critical components meet operational requirements in the most demanding deployment scenarios.

Conclusion

The exceptional power handling capacity of High Power Waveguide Differential Phase Shift Circulators results from the sophisticated integration of advanced structural design elements and carefully selected materials. Through optimized waveguide geometry, effective thermal management, and specialized ferrite configurations, these crucial components reliably manage extreme power levels while maintaining signal integrity. Advanced Microwave Technologies' expertise in this specialized field enables the creation of circulators that excel in the most demanding applications across satellite communications, defense, and aerospace sectors.

Are you developing a high-power microwave system that demands exceptional performance and reliability? Advanced Microwave Technologies offers customized High Power Waveguide Differential Phase Shift Circulators tailored to your specific requirements, backed by over 20 years of manufacturing excellence and comprehensive technical support. Our ISO-certified and RoHS-compliant products deliver unmatched performance with rapid delivery times and competitive pricing. Contact our expert team today at sales@admicrowave.com to discuss how our advanced microwave solutions can elevate your system's capabilities.

References

1. Johnson, R.M. & Williams, P.K. (2023). "Thermal Management Strategies in High-Power Microwave Components." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1829-1845.

2. Zhang, L., Chen, X., & Ramirez, A. (2022). "Advanced Ferrite Materials for High-Power Microwave Applications." Journal of Materials Science, 57(12), 9283-9301.

3. Patel, S.V. & Nguyen, H.T. (2023). "Waveguide Circulator Design for Extreme Power Handling in Defense Applications." International Journal of RF and Microwave Computer-Aided Engineering, 33(5), 23661.

4. Kowalski, M. & Dorfman, B. (2022). "Manufacturing Precision Requirements for High-Performance Microwave Circulators." Precision Engineering, 73, 112-128.

5. Li, Y., Garcia, D., & Thompson, K.L. (2023). "Environmental Testing Methodologies for Ruggedized Microwave Components." IEEE Aerospace and Electronic Systems Magazine, 38(3), 14-29.

6. Ahmed, F. & Nakamura, T. (2022). "Differential Phase Shift Circulators: Principles and Advanced Applications in Modern Radar Systems." Microwave Journal, 65(8), 32-48.

YOU MAY LIKE

VIEW MOREWaveguide Fixed Attenuator

VIEW MOREWaveguide Fixed Attenuator VIEW MOREHigh Power Waveguide Circulator

VIEW MOREHigh Power Waveguide Circulator VIEW MOREHigh Power Waveguide Differential Phase Shift Circulator

VIEW MOREHigh Power Waveguide Differential Phase Shift Circulator VIEW MOREWaveguide Coupling Fixed Attenuator

VIEW MOREWaveguide Coupling Fixed Attenuator VIEW MOREWaveguide Variable Attenuator

VIEW MOREWaveguide Variable Attenuator VIEW MOREWG Isolator

VIEW MOREWG Isolator VIEW MOREHigh Power Waveguide Isolator

VIEW MOREHigh Power Waveguide Isolator VIEW MOREHigh Power Waveguide Differential Phase Shift Isolator

VIEW MOREHigh Power Waveguide Differential Phase Shift Isolator