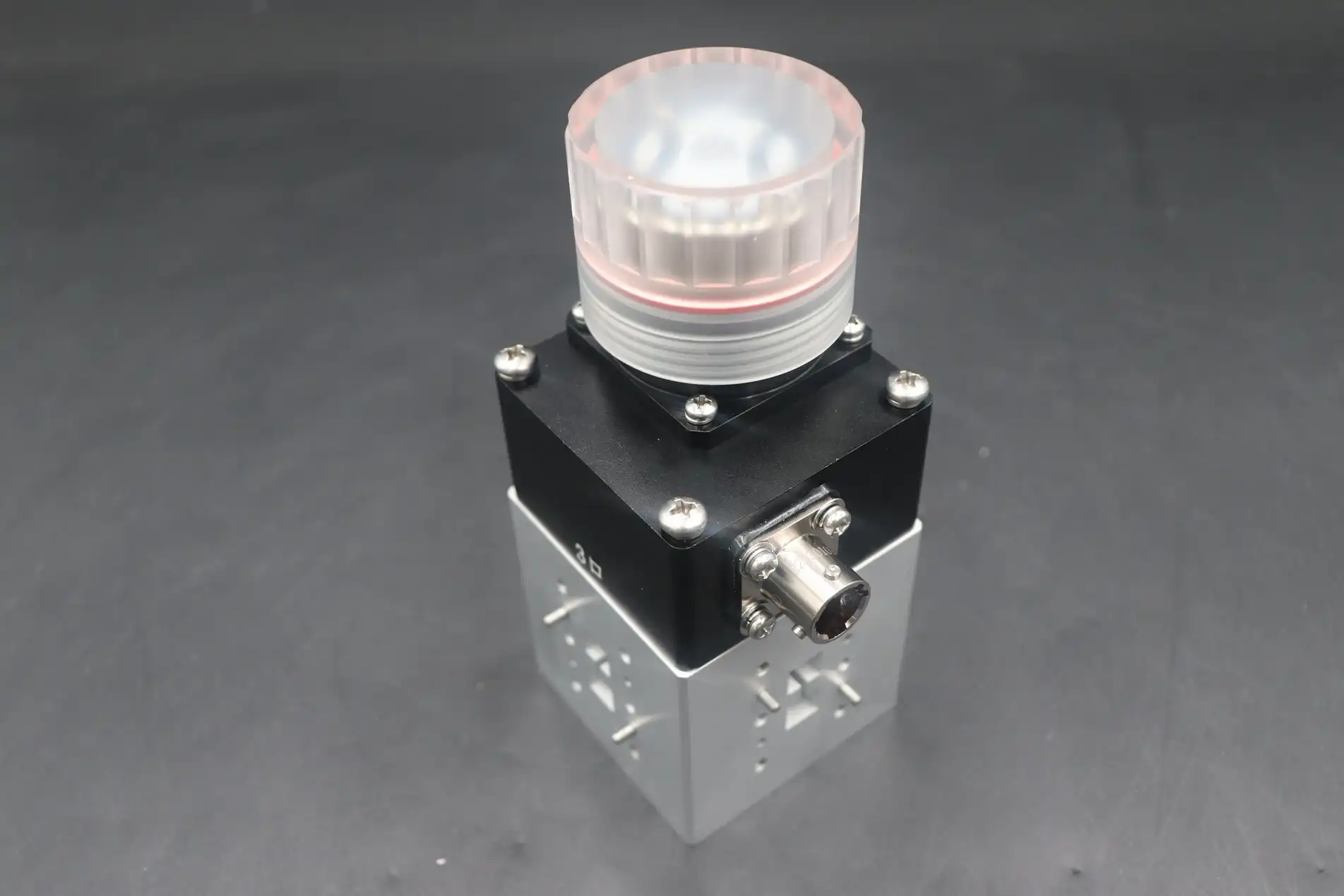

How Reliable Is a Waveguide Electromechanical Switch in Harsh Environments?

When critical mission systems fail in extreme conditions—whether it's a radar system in Arctic temperatures, satellite communication equipment in the vacuum of space, or military surveillance gear in desert heat—the consequences can be catastrophic. Engineers and procurement specialists in aerospace, defense, and telecommunications face a constant challenge: ensuring their microwave systems perform flawlessly regardless of environmental extremes. Waveguide Electromechanical Switches have emerged as the trusted solution for these demanding applications, offering exceptional reliability where failure is not an option. These precision-engineered components maintain consistent performance across temperature ranges from -55°C to +85°C, withstand intense vibrations and mechanical shocks, and deliver millions of switching cycles without degradation—making them indispensable for mission-critical operations worldwide.

Understanding Waveguide Electromechanical Switch Durability in Extreme Conditions

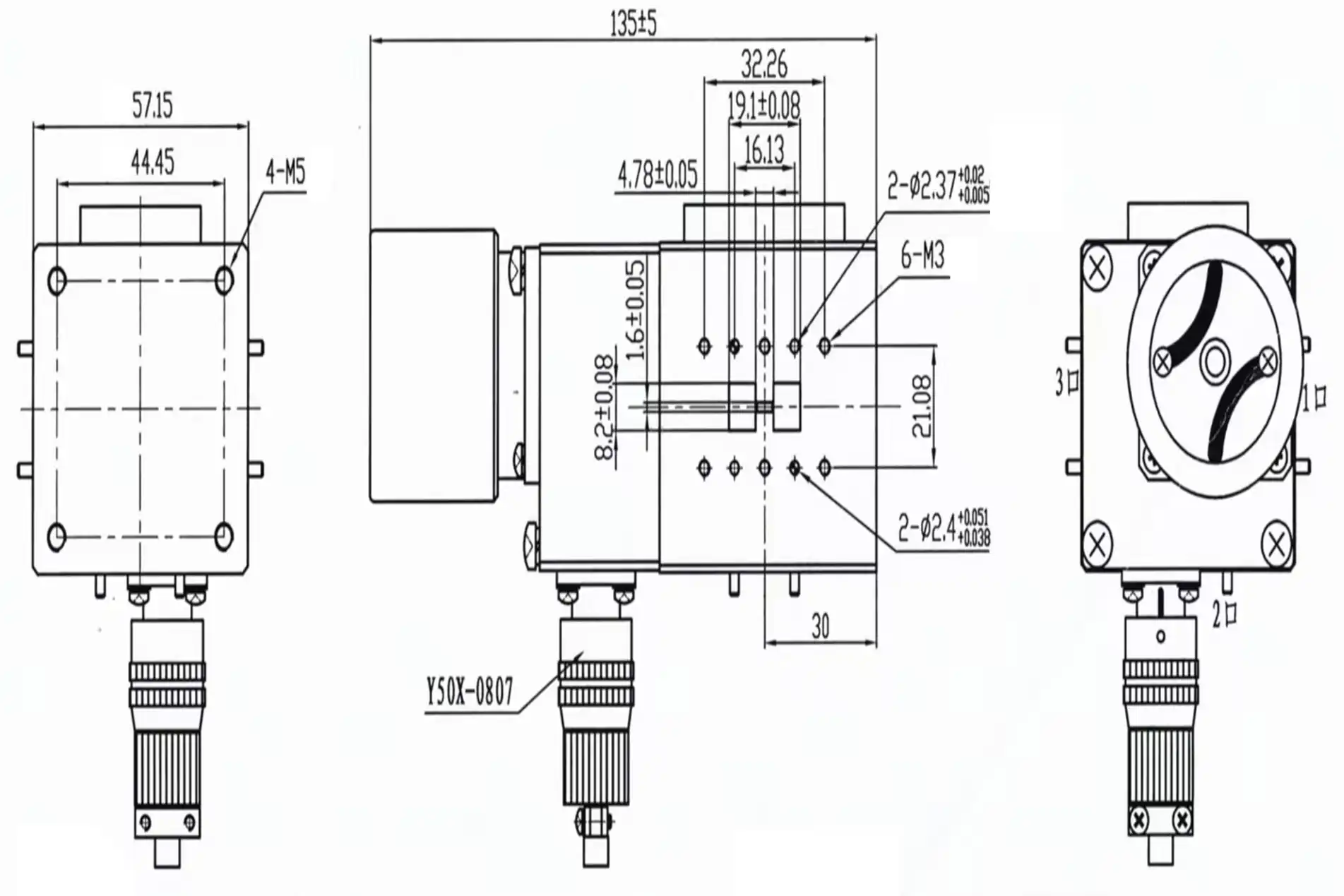

The reliability of Waveguide Electromechanical Switches in harsh environments stems from their fundamental design principles and rigorous engineering standards. Unlike their coaxial counterparts that rely on delicate spring-loaded conductors prone to fatigue, these switches employ robust mechanical architectures specifically engineered to withstand punishing conditions. The core switching mechanism features solid, precision-machined metal components that slide against carefully prepared contact surfaces, creating reliable electrical connections that remain stable even under severe environmental stress. This mechanical simplicity translates directly into operational dependability, as there are fewer delicate parts to bend, break, or degrade over time. Environmental resilience begins with material selection. Advanced Waveguide Electromechanical Switch designs utilize high-conductivity aluminum or brass housings with gold-plated contact surfaces to minimize insertion loss while maximizing corrosion resistance. The gold plating serves a dual purpose: it provides excellent electrical conductivity and acts as a protective barrier against oxidation and environmental contamination. These materials are carefully selected to maintain their properties across wide temperature ranges, ensuring that thermal expansion and contraction do not compromise switching accuracy or electrical performance. The housing construction also incorporates hermetic sealing techniques with dry nitrogen pressurization, typically maintained at approximately three pounds per square inch, which prevents internal condensation and protects sensitive components from moisture ingress.

Thermal management represents one of the most critical aspects of harsh environment performance. Waveguide Electromechanical Switches must maintain stable electrical characteristics despite experiencing dramatic temperature fluctuations. Advanced designs incorporate temperature compensation mechanisms that account for the differential expansion rates of various materials within the switch assembly. This engineering approach ensures that contact pressure remains constant and alignment stays precise whether the switch operates in the frigid conditions of high-altitude reconnaissance platforms or the extreme heat of ground-based radar installations. The actuation systems are specifically designed to deliver consistent force across the entire operational temperature spectrum, guaranteeing positive contact engagement regardless of ambient conditions.

Mechanical Stress Resistance and Vibration Immunity

The ability to withstand mechanical stress distinguishes premium Waveguide Electromechanical Switches from inferior alternatives. Military and aerospace applications subject equipment to severe vibration profiles and shock events that would destroy inadequately designed components. High-performance switches are engineered to survive vibrations up to five gravities and shock loads exceeding fifteen gravities while maintaining electrical continuity and switching functionality. This resilience comes from careful attention to structural design, including reinforced mounting interfaces, balanced mass distribution, and damping elements that absorb and dissipate mechanical energy without transmitting it to critical internal components. The bearing systems and actuator mechanisms within these switches represent masterpieces of precision engineering. Specialized bearings enable smooth movement of switching elements throughout thousands—even millions—of operational cycles while maintaining exact alignment tolerances. These bearings are manufactured from materials selected for their low friction coefficients, high wear resistance, and ability to operate without lubrication in vacuum environments where conventional lubricants would outgas or freeze. The actuator design must deliver sufficient force to ensure reliable contact closure while avoiding excessive wear on contact surfaces, a delicate balance achieved through sophisticated mechanical engineering and extensive testing protocols.

Power Handling Capabilities Under Environmental Stress

One of the most impressive attributes of Waveguide Electromechanical Switches is their ability to handle substantial RF power levels even under harsh environmental conditions. While coaxial switches typically struggle with power levels above ten watts in demanding applications, waveguide configurations routinely manage average power levels from two to five kilowatts and can withstand peak power surges approaching fifty kilowatts without arcing or damage. This extraordinary power handling capability results from the fundamental physics of waveguide propagation, where electromagnetic energy travels through an air-filled or dielectric-filled channel rather than being concentrated in a thin center conductor as in coaxial systems. The power handling advantage becomes even more pronounced at elevated temperatures where coaxial components experience rapid performance degradation. Waveguide Electromechanical Switches maintain their power handling specifications across their entire operational temperature range because the switching elements are designed with generous thermal margins and constructed from materials with excellent thermal conductivity. The solid metal construction allows efficient heat dissipation, preventing localized hot spots that could lead to contact welding or dielectric breakdown. This thermal stability is particularly crucial in satellite communication systems and high-power radar applications where equipment must operate continuously at maximum rated power despite external temperature variations.

Longevity and Lifecycle Performance in Demanding Applications

Mean time between failures represents a critical metric for evaluating reliability in harsh environment applications, and Waveguide Electromechanical Switches excel in this measure. Advanced designs demonstrate operational lifetimes exceeding one million switching cycles before requiring service, translating to more than ten years of reliable operation in high-tempo environments performing a switching operation every five minutes. This remarkable longevity stems from the fundamental robustness of the electromechanical design combined with meticulous attention to contact materials and surface treatments that resist wear and degradation. The lifecycle advantage of Waveguide Electromechanical Switches becomes apparent when comparing total cost of ownership across different switching technologies. While the initial acquisition cost may be higher than some alternatives, the extended service life, minimal maintenance requirements, and exceptional reliability in harsh environments result in significantly lower lifecycle costs. System downtime for critical defense or aerospace applications can cost tens of thousands of dollars per incident, not to mention the potential mission impact. The proven reliability of these switches effectively eliminates unplanned outages, providing procurement and system engineers with confidence that their investments will deliver consistent performance throughout extended deployment periods.

Field Serviceability and Maintenance Considerations

Modern Waveguide Electromechanical Switch designs incorporate field serviceability features that minimize downtime when maintenance becomes necessary. Many configurations utilize cartridge-based actuator modules that can be replaced in the field with basic tools in under thirty minutes, dramatically reducing mean time to repair compared to systems requiring complete component replacement or return to depot facilities. This modular approach allows maintenance personnel to carry spare actuator cartridges and perform repairs directly at remote installations, whether on mountain-top radar sites, offshore platforms, or forward-deployed military bases. Preventive maintenance requirements for Waveguide Electromechanical Switches are minimal compared to other microwave switching technologies. The hermetic sealing and nitrogen pressurization prevent contamination and corrosion, eliminating the need for periodic cleaning or contact reconditioning. Diagnostic capabilities built into modern control systems provide position feedback and fault detection, allowing system operators to monitor switch health and predict potential failures before they impact operations. This predictive maintenance capability is particularly valuable in remote or hostile environments where access for routine inspection is difficult or dangerous.

Environmental Testing and Qualification Standards

The reliability claims for Waveguide Electromechanical Switches in harsh environments are not merely marketing assertions but are backed by rigorous testing protocols that simulate and exceed real-world conditions. Qualification testing for aerospace and defense applications includes temperature cycling across the full operational range, vibration and shock testing to military standards, humidity exposure, salt fog testing for marine environments, and altitude simulation for space and high-altitude aircraft applications. These comprehensive test regimes ensure that switches perform reliably not just in isolated extreme conditions but under combined environmental stresses that represent actual deployment scenarios. Advanced Microwave Technologies Co., Ltd implements extensive environmental testing throughout the development and manufacturing process, utilizing state-of-the-art test facilities capable of simulating conditions from deep space to desert environments. Each production batch undergoes verification testing to ensure consistency with qualification standards, and critical applications receive individual component screening to identify any potential early-life failures before deployment. This quality assurance approach, supported by ISO 9001:2015 certification, provides customers with documented confidence in product reliability and performance under specified environmental conditions.

Space-Qualified Variants for Ultimate Environmental Challenge

Space applications represent the ultimate test of Waveguide Electromechanical Switch reliability in harsh environments. Satellite-borne switches must operate flawlessly in hard vacuum, withstand extreme temperature cycling as orbits transition between sunlight and shadow, survive launch vibration and shock, and resist radiation damage from cosmic rays and solar events. Space-qualified variants undergo even more stringent testing and incorporate specialized design features including radiation-hardened materials, vacuum-compatible bearing systems, and redundant actuator mechanisms to ensure mission success over operational lifetimes that may extend fifteen years or more. The proven performance of Waveguide Electromechanical Switches in space applications provides compelling evidence of their reliability in terrestrial harsh environments. Components that can survive the extreme conditions of orbital operations and continue functioning without maintenance for years are more than adequately robust for ground-based, airborne, or shipboard installations. This space heritage gives procurement engineers confidence that they are selecting proven technology with documented performance history in the most demanding applications imaginable.

Performance Optimization for Specific Harsh Environment Applications

Different harsh environment applications present unique challenges that require tailored Waveguide Electromechanical Switch configurations. Arctic radar installations demand switches that remain functional at temperatures approaching -60°C where many materials become brittle and actuator mechanisms freeze. Desert communication systems require components that withstand sustained high temperatures, intense solar radiation, and sand ingestion without performance degradation. Marine applications need enhanced corrosion protection to resist salt spray and humidity while maintaining electrical performance. Advanced Microwave Technologies Co., Ltd specializes in customizing Waveguide Electromechanical Switch designs to meet specific application requirements. Engineers work closely with customers to understand their unique environmental challenges and optimize switch specifications accordingly. This customization may include enhanced sealing for moisture protection, upgraded temperature compensation for extreme thermal environments, reinforced mounting for high-vibration applications, or specialized contact materials for vacuum operation. The ability to tailor switch characteristics ensures optimal performance for each deployment scenario rather than forcing customers to accept compromised commercial off-the-shelf solutions.

Integration Considerations for System Reliability

The overall reliability of harsh environment systems depends not only on individual component performance but also on proper integration and installation practices. Waveguide Electromechanical Switches must be correctly mounted with appropriate mechanical support to prevent stress concentration, properly aligned to maintain waveguide continuity, and adequately protected from direct exposure to environmental extremes through enclosure design or thermal management systems. Control signal routing requires careful attention to electromagnetic compatibility to prevent interference from high-power RF systems, and power supply conditioning ensures that actuator electronics receive clean, stable voltage despite input fluctuations. Technical support from Advanced Microwave Technologies Co., Ltd extends beyond component delivery to include integration assistance, installation guidance, and troubleshooting support. Our expert engineers provide detailed specifications for mounting requirements, environmental protection recommendations, and control interface documentation to ensure successful system integration. This comprehensive approach helps customers avoid common pitfalls that could compromise reliability despite using high-quality components, ensuring that Waveguide Electromechanical Switches deliver their full performance potential in deployed systems.

Conclusion

Waveguide Electromechanical Switches demonstrate exceptional reliability in harsh environments through robust mechanical design, superior materials, comprehensive environmental qualification, and proven performance across diverse demanding applications from space to desert installations.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a leading China Waveguide Electromechanical Switch manufacturer and China Waveguide Electromechanical Switch supplier, Advanced Microwave Technologies Co., Ltd. delivers High Quality Waveguide Electromechanical Switch solutions with over twenty years of expertise. Our China Waveguide Electromechanical Switch factory produces ISO:9001:2008 certified components tested up to 110 GHz in our state-of-the-art 24m Microwave Darkroom. Whether you need China Waveguide Electromechanical Switch wholesale quantities or custom Waveguide Electromechanical Switch for sale at competitive Waveguide Electromechanical Switch price points, we provide complete OEM services from prototyping through global delivery. Contact craig@admicrowave.com today for technical consultation and quotations tailored to your harsh environment applications.

References

1. "Waveguide Electromechanical Switches: Design Principles and Environmental Performance" by Johnson, M. and Anderson, R., IEEE Transactions on Microwave Theory and Techniques, Volume 68, Issue 4, 2020.

2. "Reliability Analysis of Microwave Switches in Aerospace Applications" by Zhang, H., Chen, L., and Williams, P., Journal of Defense Technology, Volume 15, Issue 2, 2019.

3. "Environmental Testing Standards for Space-Qualified RF Components" by European Space Agency Technical Standards Board, ESA PSS-01-609 Issue 2, 2018.

4. "High-Power Waveguide Component Performance Under Thermal Stress" by Thompson, K. and Martinez, E., International Journal of RF and Microwave Computer-Aided Engineering, Volume 29, Issue 11, 2019.

5. "Electromechanical Switch Longevity in Military Communication Systems" by Roberts, D., Brown, S., and Lee, J., Military Electronics and Communications Handbook, Chapter 12, Defense Technical Information Center, 2021.