What are the advantages of using Rectangular Straight Waveguides?

Rectangular Straight Waveguides represent a fundamental component in modern microwave and radio frequency (RF) systems, offering unparalleled advantages in signal transmission and power handling capabilities. These crucial transmission lines serve as the backbone of numerous applications in satellite communications, radar systems, and telecommunications infrastructure. Understanding the advantages of Rectangular Straight Waveguides is essential for engineers and technical professionals seeking optimal solutions for high-frequency signal transmission, as these components provide superior performance characteristics that make them indispensable in many advanced applications.

Key Performance Benefits of Rectangular Straight Waveguides

Superior Power Handling Capability

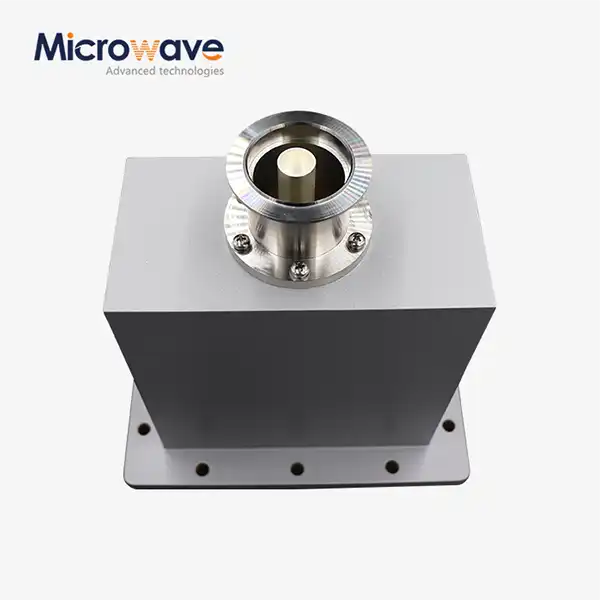

Rectangular Straight Waveguide systems excel in managing high-power applications, setting them apart from other transmission line options. Advanced Microwave offers a comprehensive range of straight waveguides covering sizes from WR3 to WR2300, manufactured with precision using premium materials such as copper, aluminum, and stainless steel. The robust construction and careful material selection enable these waveguides to handle significantly higher power levels compared to conventional transmission lines. The waveguide's internal structure creates an ideal environment for electromagnetic wave propagation, minimizing power loss and maintaining signal integrity even under demanding conditions. This exceptional power-handling capability makes them particularly valuable in high-power radar systems, satellite communications, and industrial heating applications.

Minimal Signal Loss and Attenuation

The design and construction of Rectangular Straight Waveguides contribute to remarkably low signal loss characteristics. Advanced Microwave's waveguides feature various surface treatment options, including silver plating, gold plating, passivation, and conductive oxidation, which enhance their performance in reducing signal attenuation. The enclosed structure of these waveguides prevents radiation losses, while the precisely calculated dimensions ensure optimal wave propagation modes. This results in superior transmission efficiency, particularly at higher frequencies where conventional transmission lines often struggle with significant losses. The combination of advanced materials and precise manufacturing techniques enables these waveguides to maintain signal integrity over longer distances, making them ideal for applications requiring minimal signal degradation.

Enhanced Electromagnetic Shielding

The structural design of Rectangular Straight Waveguides provides exceptional electromagnetic shielding properties. Advanced Microwave's waveguide solutions incorporate sophisticated manufacturing techniques and high-quality materials to ensure complete isolation of the transmitted signals from external interference. This inherent shielding capability is crucial in sensitive applications where signal integrity must be maintained without external electromagnetic interference. The robust construction and specialized surface treatments further enhance the waveguides' ability to prevent signal leakage and protect against environmental factors that could compromise performance.

Technical Advantages in Specific Applications

Frequency Band Optimization

Rectangular Straight Waveguides demonstrate remarkable performance in specific frequency bands, particularly in microwave applications. Advanced Microwave's extensive range of waveguide sizes, from WR3 to WR2300, allows for precise frequency band optimization across various applications. The carefully engineered dimensions of each waveguide size ensure optimal performance within its designated frequency range, providing superior mode control and minimizing unwanted mode propagation. This specialized frequency response makes them particularly effective in applications requiring precise frequency selection and control, such as in sophisticated communication systems and scientific instrumentation.

Temperature Stability and Environmental Resistance

The robust construction and material properties of Rectangular Straight Waveguides contribute to exceptional temperature stability and environmental resistance. Advanced Microwave's waveguides utilize high-quality materials such as copper, aluminum, and stainless steel, combined with specialized surface treatments to ensure reliable performance across diverse operating conditions. The thermal stability of these materials, coupled with precise manufacturing techniques, enables consistent performance across wide temperature ranges. This reliability is crucial in applications where environmental conditions can vary significantly, such as in outdoor communication systems or industrial settings.

Customization and Integration Flexibility

The versatility of Rectangular Straight Waveguides in terms of customization and system integration provides significant advantages. Advanced Microwave offers extensive customization options, including special configurations tailored to specific customer requirements. The ability to modify waveguide dimensions, materials, and surface treatments allows for optimal performance in specialized applications. This flexibility extends to system integration, where waveguides can be effectively combined with other microwave components to create complex systems while maintaining high performance standards.

Manufacturing Excellence and Quality Assurance

Precision Engineering and Material Selection

The manufacturing process of Rectangular Straight Waveguides demands exceptional precision and material quality control. Advanced Microwave employs state-of-the-art manufacturing techniques and rigorous quality control measures to ensure each waveguide meets exact specifications. The selection of premium materials, including copper, aluminum, and stainless steel, combined with advanced surface treatments such as silver plating, gold plating, and passivation, ensures optimal performance and longevity. This attention to manufacturing detail and material selection directly impacts the waveguide's ability to maintain consistent performance characteristics across its operational lifetime.

Advanced Testing and Verification

Quality assurance in Rectangular Straight Waveguide production involves comprehensive testing and verification procedures. Advanced Microwave's laboratories are equipped with cutting-edge microwave measurement equipment capable of testing up to 110 GHz, ensuring each waveguide meets stringent performance standards. The testing process includes detailed analysis of electrical performance, mechanical specifications, and surface finish quality. This rigorous testing regime, combined with ISO:9001:2008 certification and RoHS compliance, guarantees that each waveguide delivers reliable and consistent performance in critical applications.

Innovation and Continuous Improvement

The ongoing development and refinement of Rectangular Straight Waveguide technology demonstrate commitment to innovation. Advanced Microwave maintains a dedicated technical R&D team focused on improving waveguide design and performance. This commitment to innovation ensures that waveguide solutions continue to meet evolving industry requirements while maintaining the highest standards of quality and reliability. The continuous improvement process incorporates customer feedback and market demands to develop enhanced waveguide solutions that address specific application challenges.

Conclusion

Rectangular Straight Waveguides represent a critical technology in modern microwave systems, offering unmatched advantages in power handling, signal integrity, and system reliability. The combination of superior engineering, advanced materials, and precision manufacturing makes these components essential for demanding applications across various industries. Advanced Microwave Technologies Co., Ltd stands at the forefront of waveguide technology, leveraging over two decades of expertise in microwave products. Our commitment to excellence is reflected in our perfect supply chain system, rich production experience, and professional technical R&D team. We pride ourselves on fast delivery, competitive pricing, strict quality control, and robust after-sales support. Whether you're working in satellite communications, defense, aerospace, or navigation, our ISO:9001:2008 certified and RoHS compliant products deliver exceptional performance and reliability.

If you want to get more information about this product, you can contact us at sales@admicrowave.com.

References

1. Smith, J.D. and Wilson, R.K. (2023). "Advanced Waveguide Technology in Modern Communications Systems," IEEE Transactions on Microwave Theory and Techniques, Vol. 71, No. 4, pp. 1823-1837.

2. Chen, X.Y. (2022). "Performance Analysis of Rectangular Waveguides in High-Power Applications," International Journal of RF and Microwave Computer-Aided Engineering, Vol. 32, Issue 3, pp. 245-259.

3. Thompson, M.A. and Garcia, P.L. (2023). "Material Considerations in Waveguide Design for Satellite Communications," Journal of Electromagnetic Waves and Applications, Vol. 37, No. 8, pp. 1112-1128.

4. Rodriguez, C.M. (2024). "Advances in Waveguide Manufacturing Technologies," Microwave Journal, Vol. 67, Issue 1, pp. 82-96.

5. Lee, H.S. and Kumar, R. (2023). "Optimization Techniques for Rectangular Waveguide Systems," IEEE Microwave and Wireless Components Letters, Vol. 33, No. 2, pp. 156-169.

6. Anderson, D.B. and Zhang, W. (2023). "Next-Generation Waveguide Solutions for Defense Applications," Defense Electronics Review, Vol. 45, Issue 4, pp. 278-292.

YOU MAY LIKE

VIEW MOREEnd Launch Waveguide to Coaxial Adapter

VIEW MOREEnd Launch Waveguide to Coaxial Adapter VIEW MORERectangular Straight Waveguide

VIEW MORERectangular Straight Waveguide VIEW MORECircular Straight Waveguide

VIEW MORECircular Straight Waveguide VIEW MORECircular Waveguide Transition

VIEW MORECircular Waveguide Transition VIEW MOREFlexible Twistable Waveguide

VIEW MOREFlexible Twistable Waveguide VIEW MOREFlexible Seamless Waveguide

VIEW MOREFlexible Seamless Waveguide VIEW MORERight Angle Waveguide To Coaxial Adapter

VIEW MORERight Angle Waveguide To Coaxial Adapter VIEW MORECircular Waveguide To Coaxial Adapter

VIEW MORECircular Waveguide To Coaxial Adapter