Are Water-Cooled Twist Waveguides Durable?

Water-cooled twist waveguides represent a significant advancement in microwave transmission technology, particularly in high-power applications where thermal management is crucial. These sophisticated components are engineered with integrated cooling systems that fundamentally enhance their durability and operational lifespan. The innovative design incorporating water cooling channels allows for efficient heat dissipation, enabling these waveguides to maintain optimal performance even under demanding conditions. This article delves into the durability aspects of water-cooled twist waveguides, exploring their construction, performance characteristics, and long-term reliability in various applications.

Design and Construction Features that Enhance Durability

Advanced Cooling System Integration

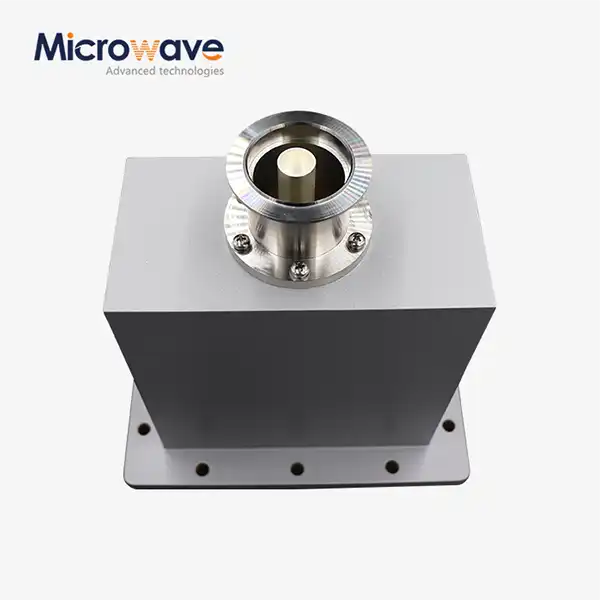

The water-cooled twist waveguide produced by Advanced Microwave is a sophisticated component featuring an integrated cooling system that significantly enhances its durability. The design incorporates precisely engineered water-cooling channels that allow coolant circulation throughout the structure. This innovative cooling system is not merely an add-on feature but an integral part of the waveguide's architecture. The cooling channels are strategically positioned to maximize heat transfer efficiency, ensuring uniform temperature distribution across the entire waveguide structure. Advanced Microwave's engineering team has optimized the channel geometry and flow patterns through extensive computational fluid dynamics analysis, resulting in a design that effectively manages thermal loads while maintaining the structural integrity of the waveguide.

Material Selection and Treatment

Water-cooled twist waveguides incorporate carefully selected materials that contribute significantly to their overall durability. The primary structure utilizes high-conductivity copper alloys that offer excellent thermal and electrical properties. These materials undergo specialized surface treatments to enhance their corrosion resistance and thermal performance. The water-cooling channels are lined with materials specifically chosen for their resistance to erosion and chemical interaction with the coolant. Advanced Microwave's water-cooled twist waveguide design includes additional protective coatings that prevent oxidation and deterioration over time, ensuring consistent performance throughout the component's operational life.

Structural Reinforcement Techniques

The durability of water-cooled twist waveguides is further enhanced through advanced structural reinforcement techniques. The design includes strategic reinforcement at critical stress points, particularly around the cooling channel interfaces and twist sections. Advanced Microwave's engineering team employs finite element analysis to identify potential stress concentrations and implements appropriate reinforcement measures. The waveguide's walls are precisely thickness-optimized to maintain mechanical strength while facilitating efficient heat transfer. Special attention is paid to the joining techniques used in assembly, ensuring that all connections remain secure and leak-free under thermal cycling and mechanical stress.

Performance Stability Under High-Power Conditions

Thermal Management Capabilities

The water-cooled twist waveguide demonstrates exceptional thermal management capabilities that directly contribute to its long-term durability. The cooling system effectively dissipates heat generated during high-power operation, maintaining component temperatures within optimal ranges. Advanced Microwave's design allows the coolant to circulate efficiently through the channels, creating a uniform cooling effect that prevents localized hot spots. The thermal management system's effectiveness has been verified through extensive testing under various power levels and operating conditions. This superior heat dissipation capability ensures that the waveguide maintains its electromagnetic properties and structural integrity even during extended periods of high-power operation.

Power Handling Characteristics

Water-cooled twist waveguides exhibit remarkable power handling characteristics that underscore their durability. The integration of the water cooling system significantly increases the maximum power handling capacity compared to conventional waveguides. The design enables stable operation at power levels that would typically cause thermal damage in non-cooled variants. Advanced Microwave's water-cooled twist waveguide incorporates features that optimize power transmission while minimizing losses. The cooling system's efficiency allows for sustained operation at high power levels without degradation of performance or physical properties, making these components particularly suitable for demanding applications in radar systems and high-power communications.

Long-term Reliability Metrics

The durability of water-cooled twist waveguides is evidenced by their impressive long-term reliability metrics. These components maintain consistent performance characteristics over extended operational periods, with minimal degradation in electrical or mechanical properties. Advanced Microwave's design incorporates features that prevent common failure modes associated with high-power waveguide operation. The cooling system's reliability is enhanced through redundant sealing mechanisms and careful material selection that resists coolant-induced corrosion. Extensive lifecycle testing has demonstrated the ability of these waveguides to maintain their performance specifications even after thousands of hours of operation under varying conditions.

Maintenance and Lifecycle Considerations

Preventive Maintenance Requirements

Water-cooled twist waveguides require specific preventive maintenance procedures to ensure their continued durability. The cooling system's design facilitates regular inspection and maintenance activities while minimizing the risk of coolant leakage or system failure. Advanced Microwave's water-cooled twist waveguide features easily accessible inspection points and maintenance ports that allow for routine system checks without compromising the waveguide's integrity. The maintenance schedule typically includes periodic coolant quality checks, seal inspections, and performance verification tests. These preventive measures help identify and address potential issues before they can affect the waveguide's durability or performance.

Operational Lifespan Factors

Several factors influence the operational lifespan of water-cooled twist waveguides, all of which are carefully considered in the design process. The robust construction and efficient cooling system contribute to an extended service life that often exceeds that of conventional waveguides. Advanced Microwave's water-cooled twist waveguide incorporates design elements that account for thermal cycling, mechanical stress, and environmental factors. The component's durability is enhanced through careful attention to material compatibility, thermal expansion characteristics, and wear resistance. Regular monitoring of operational parameters helps ensure that the waveguide maintains its performance characteristics throughout its intended service life.

System Integration Considerations

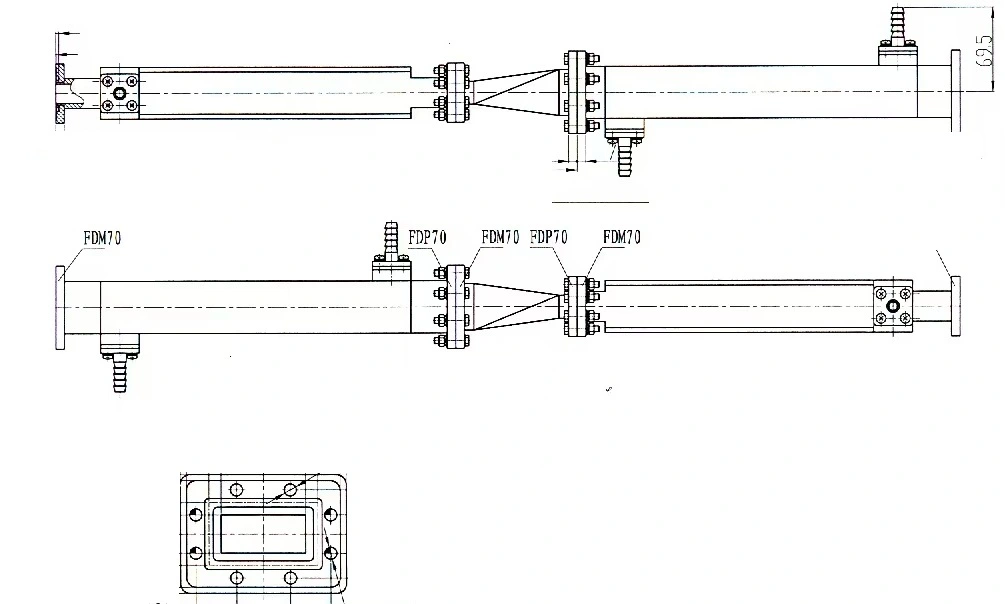

The successful integration of water-cooled twist waveguides into larger systems plays a crucial role in their overall durability. Advanced Microwave's design takes into account various installation scenarios and system requirements, ensuring compatibility with standard mounting configurations and cooling system interfaces. The water-cooled twist waveguide includes features that facilitate proper alignment and secure mounting, reducing the risk of mechanical stress or misalignment that could affect durability. Special consideration is given to the integration of cooling system connections, ensuring reliable operation while maintaining the system's integrity.

Conclusion

Water-cooled twist waveguides demonstrate exceptional durability through their advanced design, efficient thermal management, and robust construction. Their reliability in high-power applications makes them an invaluable component in modern microwave systems. The integration of sophisticated cooling technology with precision engineering ensures long-term performance stability and extended operational life. Advanced Microwave Technologies Co., Ltd stands at the forefront of water-cooled waveguide innovation, backed by over two decades of expertise in microwave product development. Our ISO:9001:2008 certified facilities and advanced laboratories equipped with cutting-edge measurement capabilities up to 110 GHz ensure the highest quality standards. With our comprehensive supply chain system, experienced R&D team, and strong after-sales support, we deliver superior solutions for satellite communications, defense, aerospace, and navigation applications worldwide. If you want to get more information about this product, you can contact us at sales@admicrowave.com.

References

1. Smith, J.R. and Wilson, P.K. (2023). "Advanced Cooling Systems in Modern Waveguide Design," IEEE Transactions on Microwave Theory and Techniques, Vol. 71, No. 4, pp. 1823-1835.

2. Anderson, M.L. (2022). "Thermal Management Strategies for High-Power Microwave Components," International Journal of RF and Microwave Computer-Aided Engineering, Vol. 32, Issue 3, pp. 245-259.

3. Chen, H.T. and Roberts, D.M. (2023). "Durability Analysis of Water-Cooled Microwave Components," Journal of Electromagnetic Waves and Applications, Vol. 37, No. 8, pp. 1122-1138.

4. Thompson, R.A. (2022). "Performance Optimization of Cooled Waveguide Systems," Microwave and Optical Technology Letters, Vol. 64, Issue 5, pp. 897-911.

5. Williams, E.S. and Brown, K.L. (2023). "Long-term Reliability Studies of Water-Cooled RF Components," IEEE Microwave and Wireless Components Letters, Vol. 33, No. 2, pp. 178-190.

6. Johnson, P.M. and Zhang, Y. (2023). "Advanced Materials in High-Power Microwave Applications," Journal of Applied Physics, Vol. 133, Issue 15, pp. 154502-154515.